Automatic CNC Offset Control Software

With AutoComp, you'll never have to worry about operator error or manually calculating tool offsets again!

Tool Wear Compensation Software

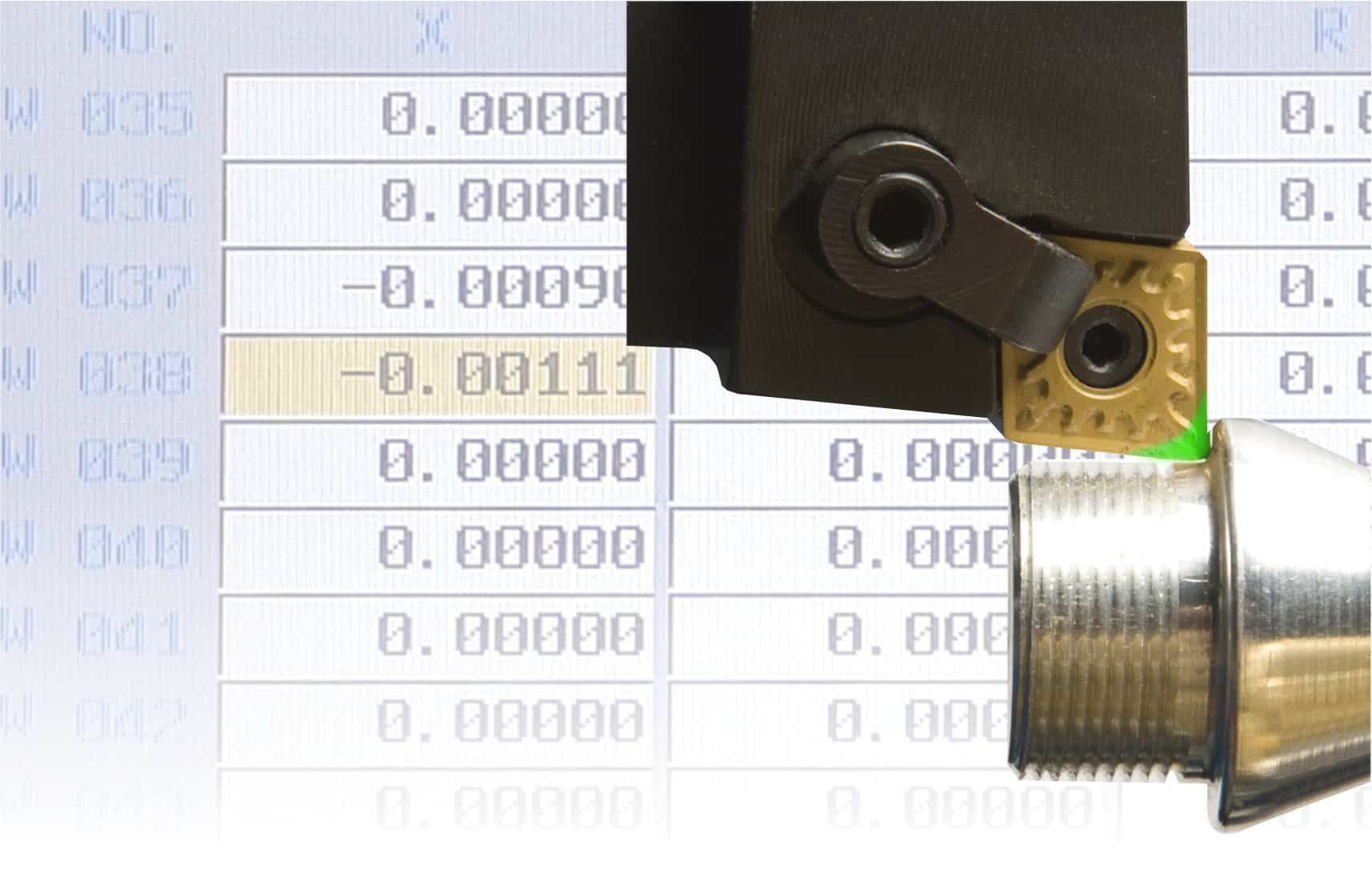

AutoComp is a Windows-based software application that reads and processes part measurements from almost any electronic gauging device, calculates the necessary tooling adjustments, and then updates offsets in the control. This happens automatically without any operator intervention.

AutoComp eliminates error associated with manual data entry and closes the loop with automatic feedback to the CNC control.

See how AutoComp works with any electronic gauging device to provide automated and error-free tool offset control!

How Does It Work?

- During setup, the user creates an AutoComp routine consisting of the essential part dimensions and inputs the parameters (tolerances and compensation limits) for each dimension

- AutoComp reads the measurement file and checks each measurement against the feature limits to calculate the correct amount to offset each tool

- AutoComp sends this information to the CNC control automatically, with no operator intervention required

Gauging Devices

Use almost any electronic gauging device to provide dimensional measurements and AutoComp will calculate the necessary tooling adjustments.

- CMMs

- Digital Tooling

- Probes

- Laser Micrometers

- Vision Systems

- Wireless Gauging Device

- Gauge Fixtures with LVDTs

Don’t see your device? Caron Engineering can write drivers to retrieve data from nearly any type/brand of electronic measurement equipment. Contact us for more information.

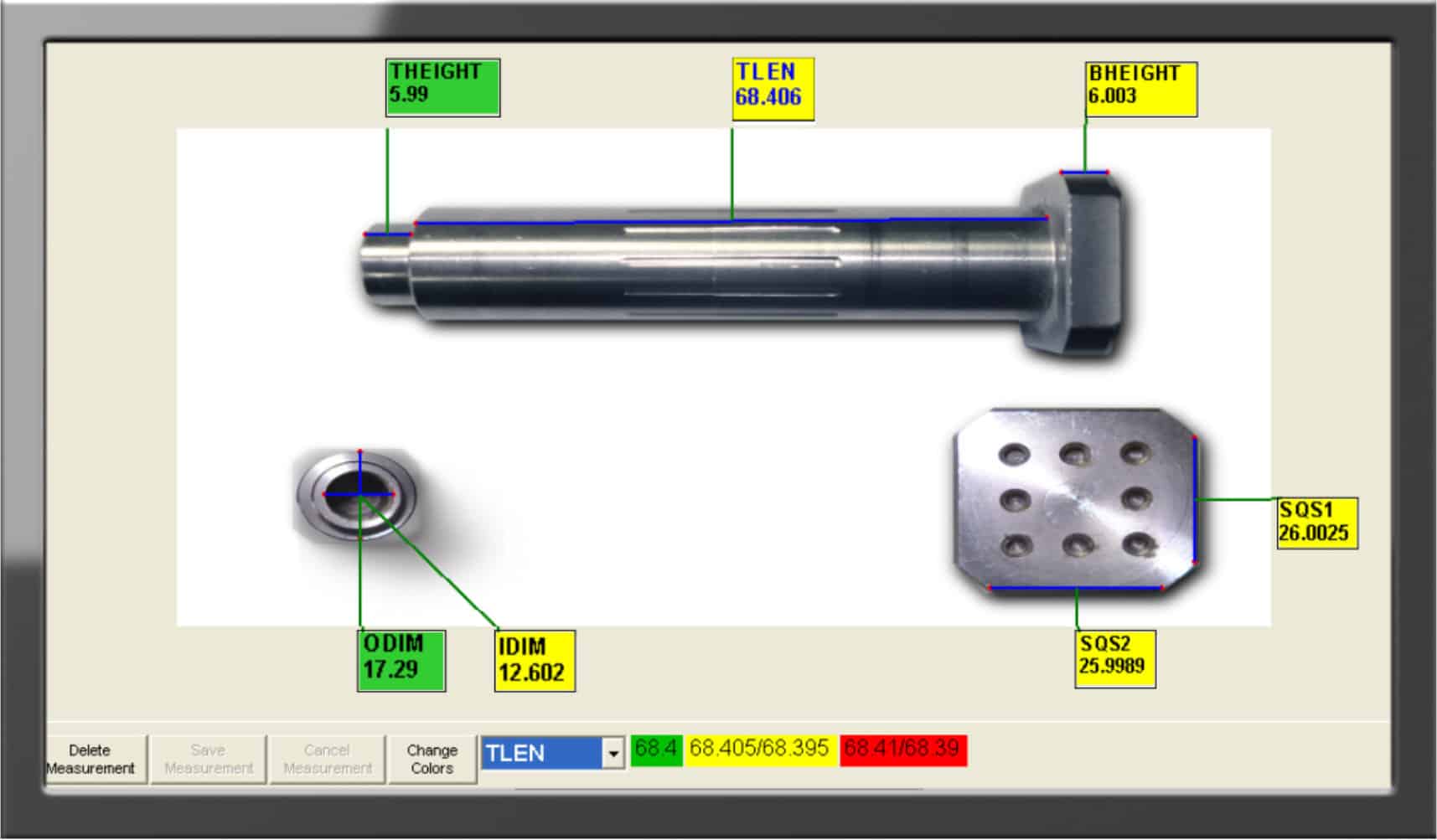

PartView

- The PartView feature displays dimensional data superimposed on a picture of your part

- JPG images can be labeled with each area of the part being measured for deviation

- Operators can more easily identify which area of the part will be compensated

Features and Benefits

- Eliminates manual data entry errors

- Interfaces directly with the CNC control

- Compiles and reports historical tool wear measurement

- Maintains acceptable tolerances of machined parts

- Notifies the operator when a tool change is needed

- Essential for closed loop and lean manufacturing

- MTConnect Compliant

All Caron Engineering products include the MTConnect protocol communications which allows us to provide meaningful data to any supervisory software, for real-time data sharing.