Machine Surface Roughness Gauge

The texture of your part's surface after machining is a critical element in achieving quality standards. Some parts demand a lower average roughness because a smoother finish is required. Other part tolerances allow an increased level of roughness because a higher texture is acceptable for the intended use of the part. No matter what the desired roughness value, by measuring the surface roughness of each machined part, we can ensure consistent quality.

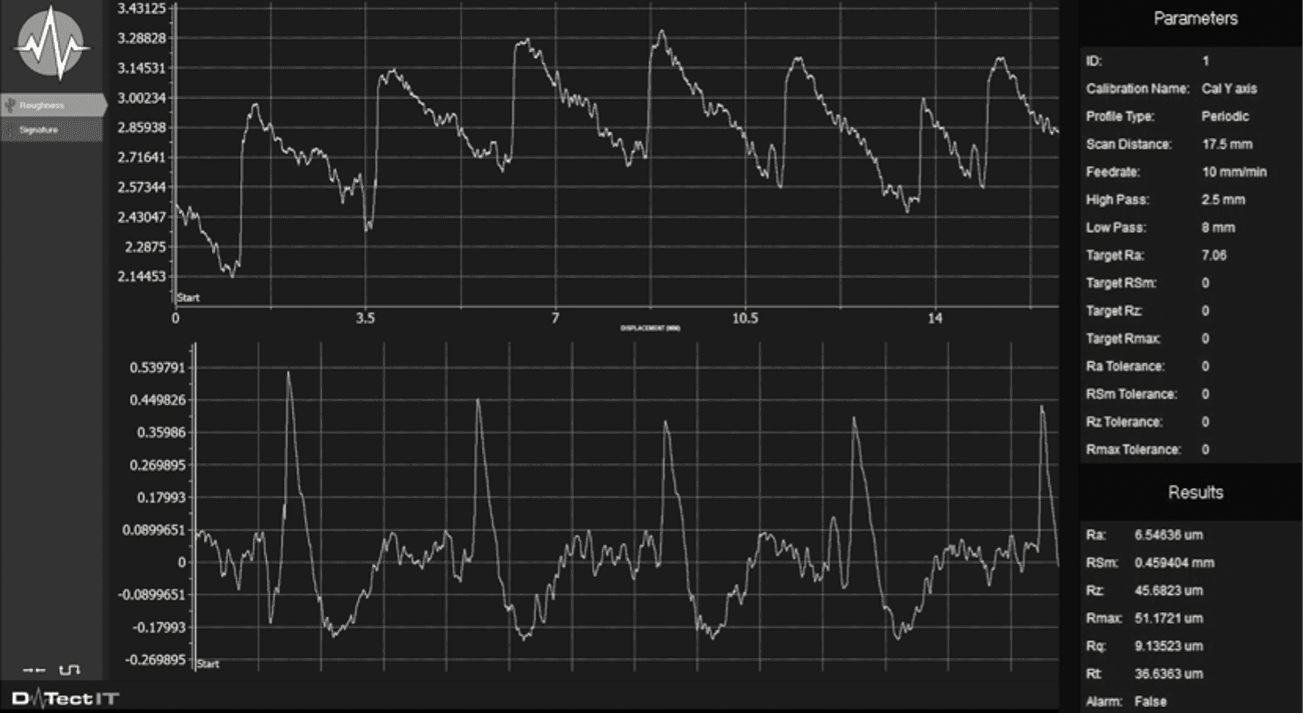

Caron Engineering's roughness analysis software works with a Blum-Novotest TC64 RG Digilog Probe as the sensor input to measure the surface texture. The RG probe is initiated by the CNC program to do an in-process scan of the part with the probe stylus. The roughness analysis software collects the scanned data from the probe, and using NIST traceable algorithms, calculates the surface roughness.

For this analysis the probe uses a 10um radius tip to provide high resolution surface scanning. The software handles all required filtering and allows the user to set scanning parameters based on the type of surface finish being measured. The in-process measurement combined with the immediate results ensure that each part has met the quality roughness standards before it even leaves the machine.

Key Features

Using this technology in the machine, the probe can be oriented to any angle and can reach any surface that the machine can locate. The in-process measurement saves cycle time by reducing the quality steps after the part is removed from the machine.

- Verifies surfaces are free of machining errors

- Maintains consistent quality of finished parts

- Allows measuring every part with in-process roughness detection

- Gives insights into cutter health by measuring after each cut

Products with Roughness Measurement Capability

CNC Sensor Analysis System