CNC Tool Monitoring: Cutting Signature Analysis

For certain cutting operations, using a fixed limit or work to monitor the condition of a cutting tool is not always the most effective solution. In these instances, the use of signature analysis provides a monitoring approach that accounts for the variable load change on the tool due to a variety of circumstances. The variations could be attributed to a change in RPM, tool path or other factors. Signature analysis is most useful for high precision or repeatable cutting operations where slight variations in tool path can have a large impact on the final product.

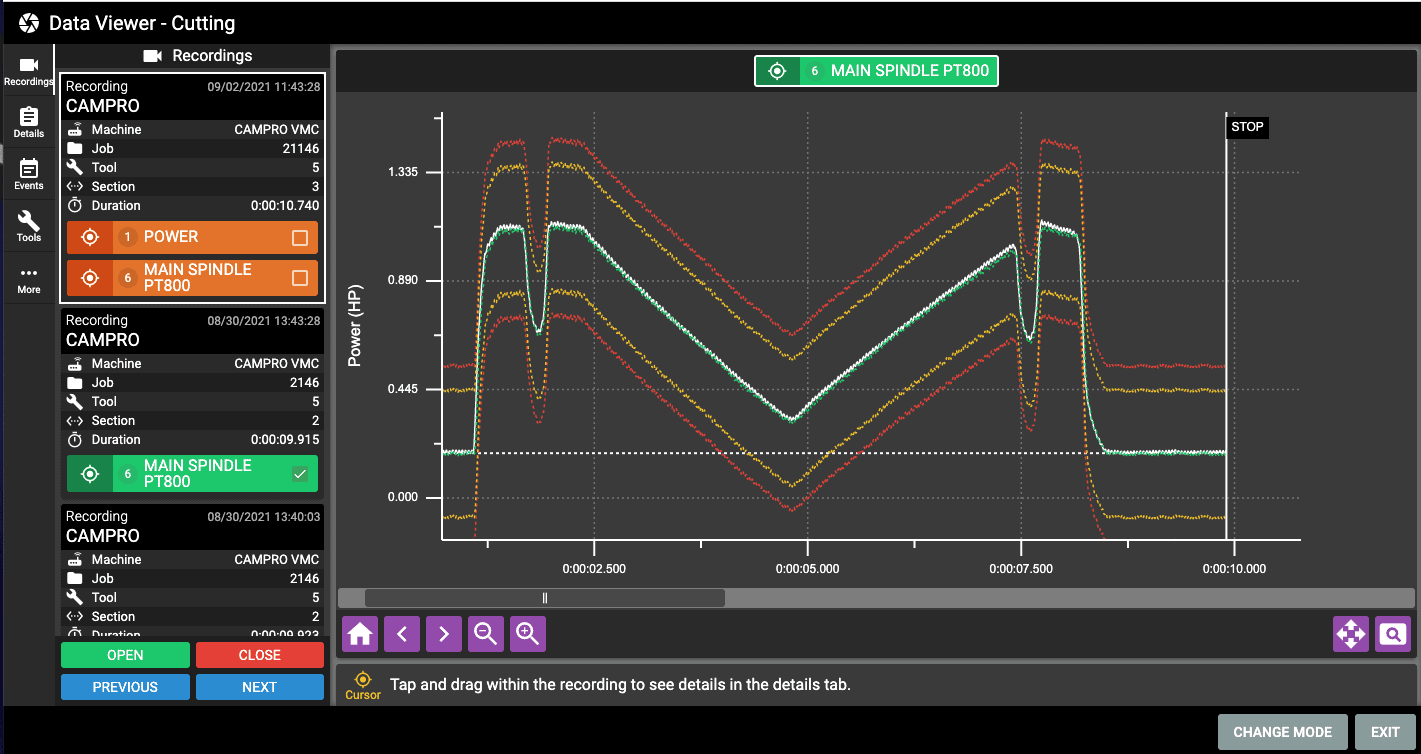

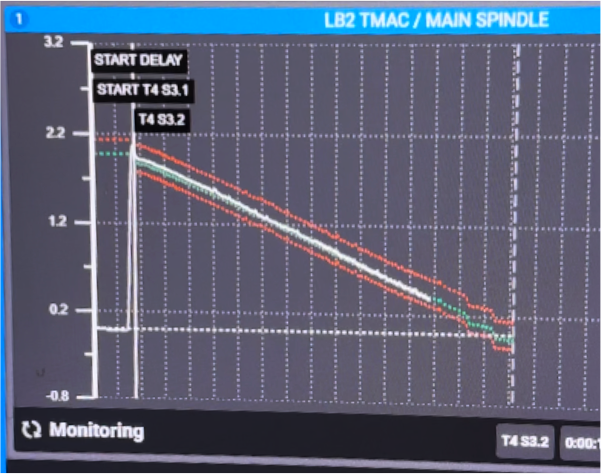

To perform this, the signature analysis software learns the entire signature (path) of a cut using any sensor type. The user can define boundaries around the learned signature, both above and below it. These boundaries define a window that the signature must stay within to satisfy a good cut. If any portion of the signature of a monitored tool exceeds the warning (yellow) or extreme (red) boundaries, an alarm is generated. Signature analysis is also another method to monitor tool wear so that we can quickly identify when a tool needs to be replaced.

The versatility of Caron Engineering's tool monitoring systems allow monitoring each tool and cutting section with the most appropriate method. This capability provides the user with the ability to switch from monitoring the work of the cutting tool to the signature analysis mode for cutting operations where it is most suitable, such as constant surface speed cuts and part-off operations.

Constant Surface Speed Cutting Operations

The signature analysis monitoring capability can be applied most notably to constant surface speed cutting operations where the material diameter changes consistently during a cut. With diameter changes, the RPM varies as the material increases or decreases causing sensor fluctuations unrelated to the tooling.

In manufacturing, this applies to such constant surface speed cutting as facing and turning operations on a CNC lathe, where the RPM is being adjusted automatically to maintain a proper chip load. The lathe starts cutting at the original diameter of the part and as it removes material, the diameter is consistently decreasing. Those RPM changes cause a fluctuation in power which is difficult to monitor with tool load monitoring. By learning the signature of the cut and setting boundaries around the learned signature, these cuts can be accurately monitored to ensure optimal surface finish.

Deep Part-Off Operations

Deep part-off operations can be challenging, and when they go wrong, they go very wrong. At the very least, you’re replacing the part-off blade. Worse yet, you end up friction welding your tool to the stock and potentially need to realign your machine. The most common modes of failure are small fractures in the cutting edges, resulting in increased load on the spindle, or more catastrophic fractures where you lose a significant portion of the insert. In the second scenario, you actually see a dip in power before the broken tool re-engages the material and quickly destroys the tool body.

With signature analysis this dip in power is easily detected. By tightly bounding the known (learned) power of the part-off cutting operations with the signature analysis warning and extreme thresholds, the system is able to protect machines from both modes of failure.

Key Features of Signature Analysis

- Monitors the entire path of a tool in cut

- Certifies optimum surface finish of each monitored part

- Alarms when any portion of the cut exceeds a user-defined boundary

- Identifies when material is missing anywhere in a cut

- Ideal for constant surface speed cutting operations

- Easily registers a dip in the power to safeguard part-off operations

Products with Signature Analysis Capability

Adaptive Tool Monitoring System

CNC Sensor Analysis System