CNC Spindle Monitoring Software

Bad spindle bearings that go undetected can lead to excessive chatter and ultimately spindle failure. The bearing analysis feature identifies when bearings need attention to help avoid costly problems.

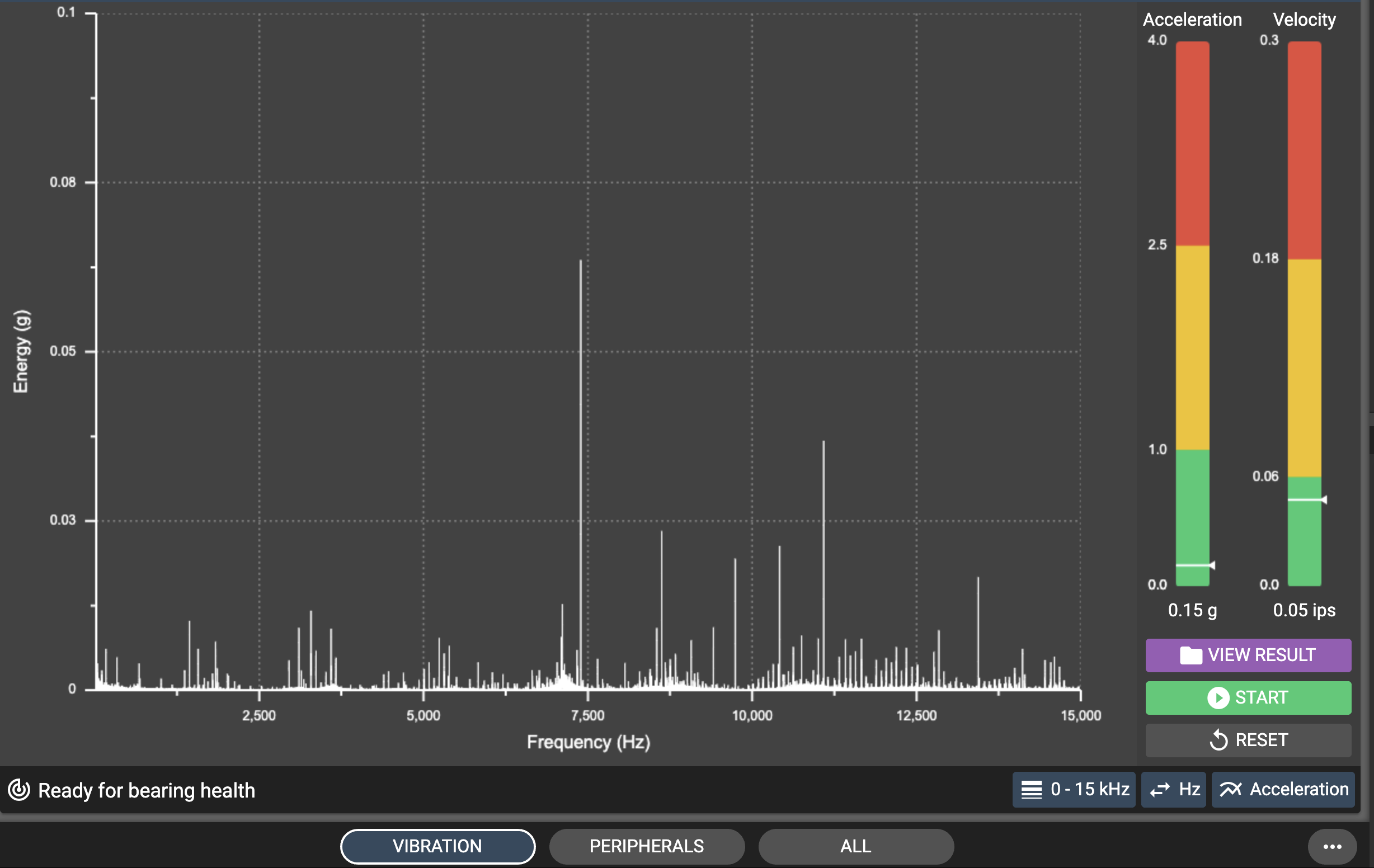

The bearing analysis software communicates with a Caron Engineering vibration sensor attached to the spindle. The vibration signal is analyzed for the acceleration signature, which tells the health of the bearings and the velocity signature, which detects misalignment, imbalance, and looseness.

- The bearing analysis is initiated through the CNC part program. Results are displayed within five seconds and the bearing report is saved to a file for analysis.

- A visual color indicator on the HMI screen shows the result of the most recent analysis. The icon appears green when the bearings are in "good or excellent health", yellow for "needs attention" and red for "needs immediate attention."

- Using the historical viewer, the user can analyze and view all previous analyses and trend bearing health data over time to predict maintenance.

Vibration Analysis Results

FEATURES

- Onscreen results are displayed within 5 seconds

- Reports are automatically generated and saved for analysis and trending

BENEFITS

- Prevents unexpected downtime

- Helps predict spindle failure

Products with Bearing Analysis Capability

Adaptive Tool Monitoring System

CNC Sensor Analysis System