Customizable CNC Machine Status Smart Light

Caron Engineering's customizable CNC machine status Smart Light System provides an easy assessment of a part's progress on a CNC program. A standard machine status light, or stack light, is used in an industrial manufacturing or process control environment to deliver real-time visual feedback to machine operators, technicians, production managers, and other factory personnel. While traditional stack lights have limited indicators showing basic machine status, the Smart Light offers over 1000 configurations that can be custom-programmed for any machine status of condition indication. with the aid of custom-programmed LED lights. With intuitive operator screens, the user can preconfigure recipes for basic light outputs, or use direct set protocol for advanced control of the light stack to dynamically change the light to correspond directly to an extensive number of manufacturing steps.

Machine Smart Light System Features

See how the Smart Light System can be customized to optimize productivity at your shop!

- 1000 available modes, 0-255 available via direct I/O

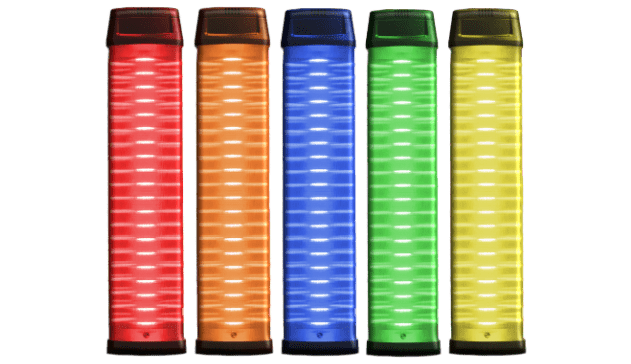

- 6 different colors (white, green, blue, yellow, red, orange), plus one (1) user-defined color

- Use multiple protocols at the same time

- Lights can be mounted/installed anywhere on the machine

- Can directly replace existing status light

- Lights can be in "Steady State", "Blinking", "Flashing" or all 3 at the same time

- Programmable audible alarm

Light Modes

The CEI Smart Light System offers a variety of modes and color options for any status indication. Modes include: Single Color, Level Mode, Segment Mode, and Run Light Mode. The status lights can be in Steady State, Blinking, Flashing, or a combination of all three at the same time. With a seemingly endless combination of color combinations and programmable buzzer tones, any machine status can be easily conveyed to operators from a distance, reducing the need for continual hands-on inspection that requires additional personnel and time. LED Smart Lights can be programmed to display unique colors, patterns, or color combinations to reflect the below statuses and countless other industry or machine specific scenarios not mentioned:

- Machine warmup state

- Transitional states

- Process or stage time remaining

- The machine requires attention from an operator

- Tool wear conditions are present

- Laser measurement is in progress or has been completed

- Machining is complete

- Countdown timers

- The machine requires additional supply (i.e. bar feeder is on the last bar)

-

SINGLE COLOR

- Lights can be any color and can be solid, blink, or flash

- Can replace existing status light

-

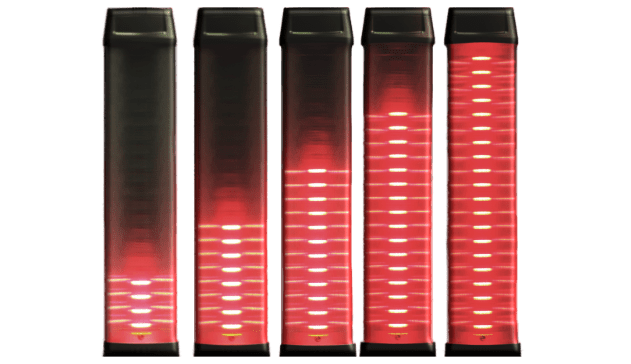

LEVEL

- 1 – 20 lights lit in succession and can be any solid color

- Used to indicate cycle status (%) or any level

-

SEGMENT

- Up to 5 light segments

- Segments can be any color and be solid, blink, or flash

-

RUN LIGHT

- Any foreground color can run over any background color

- 1 – 3 segments can be running.

- Used for special indications

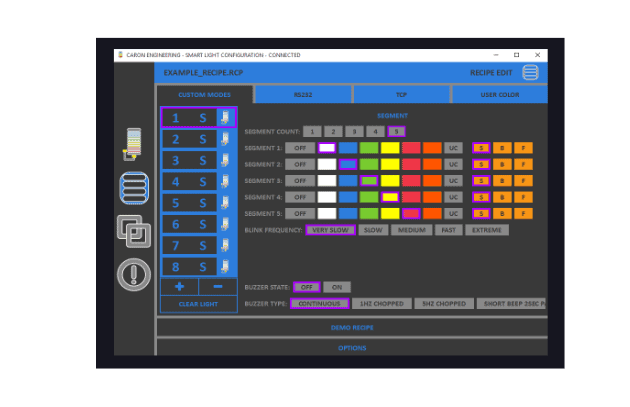

Configuration Software

RECIPE BUILDER

- Builds system configuration with custom modes and communication protocols

- Custom recipes are created to control the light by calls from the CNC program

LIVE DEMO MODE

- Used for testing all light configurations before programming recipes

All Caron Engineering products include the MTConnect protocol communications which allows us to provide meaningful data to any supervisory software, for real-time data sharing.