CNC Machine Access and User Authentication Using RFID

When it comes to machine and manufacturing software access, accountability of interactions and permissions is growing increasingly more important to monitor with the decrease of skilled labor and increase in employee turnover. Currently, most manufacturing systems and software are accessed by use of physical keys or passwords, all of which can be shared without traceability.

RFID Badge Access System

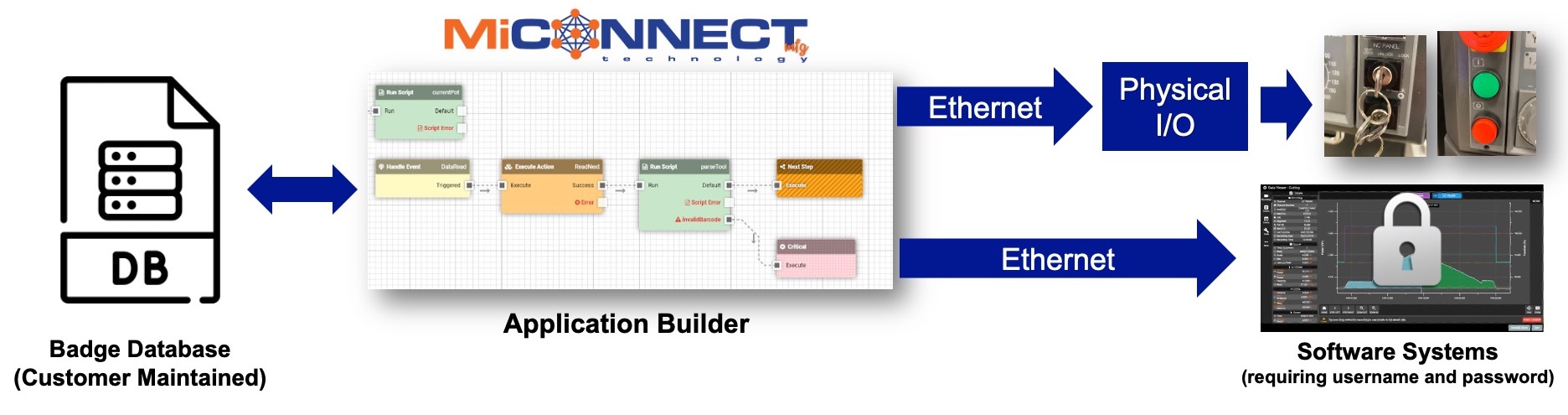

Using ELATEC Inc. RFID badge readers integrated with our MiConnect Technology solution to interface with the CNC, we can control user access to manufacturing systems, both physical and software, directly from the employee badge. MiConnect Technology is a customizable application builder for the CNC manufacturing environment that allows us to easily integrate devices and operations on a shop floor to automate processes. Using a database of user credentials and access levels, we can use MiConnect Technology to connect the user permissions to each employee badge to allow access via a simple RFID badge scan at the machine or application.

Check out this video to see how our RFID User Authentication System can safeguard access to all your manufacturing systems.

No More Keys or Passwords

Because the machine access is integrated with the employee ID badge, it alleviates the need to carry an additional access card, keys, or remember passwords. The system can be configured to grant access to specific machines or entire manufacturing lines, with individualized access to programs, screens, and application functions based on the user’s role. This eliminates the risk of unauthorized use and helps prevent unscheduled downtime when inexperienced users have unmonitored system access.

The data is maintained in a centralized location, so when employee turnover occurs, all access can be remotely removed from the badge database alleviating any issues with collecting physical assets (keys) upon exit. If the employee role changes, this can easily be updated at any time.

Fully Traceable

MiConnect Technology applications have an inherent audit log that tracks every interaction with date and time stamp. This helps provide a clear audit trail of who accessed what equipment, when they accessed it, and how long they were using the equipment. Users will be discouraged from sharing their employee badge for any system access knowing there is full accountability of their interactions.

The logs and reports can all be customized to easily display the information you need at a glance.

Safeguard Physical Systems Access

Starting a CNC machine that is not ready to be run can be catastrophic. Currently, there is nothing safeguarding the machine that prevents just anyone from pushing the start button. Using the RFID badge reader system, we can require authorization to activate the machine cycle start.

Similarly, a physical key is required to access the NC control panel to make part program edits and enter maintenance codes. Losing and sharing keys is a constant concern when it comes to safeguarding who can access the CNC control panel. With an authorized RFID badge scan, MiConnect can take over the physical key turn function to access the panel.

This ensures only authorized users are accessing these functions and provides complete traceability of each scanned interaction.

Flow chart shows how inputs and outputs tied to machine IO allow MiConnect to take over the normal physical functions of a key turn or a button press. MiConnect can also communicate user access via ethernet commands to the system.

Integrates with Caron Engineering Products

The access can also apply to all Caron Engineering products and software. For instance, our adaptive tool monitoring system, TMAC, has system securities that allow customized access within the software based on the user role. Using MiConnect technology, we can connect these unique access permissions to the employee RFID badge.