Probe Surface Scanning

The Probe Surface Scanning application provides a complete in-process surface analysis of any finished part.

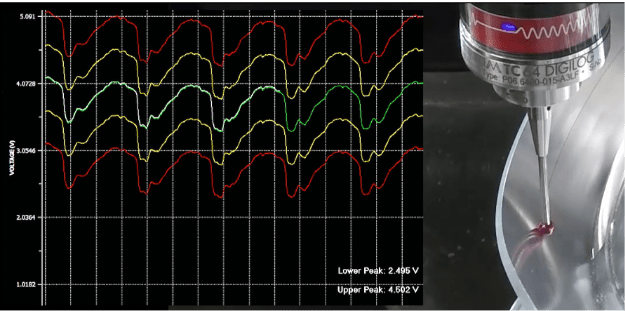

This application uses a Blum Digilog probe (see requirements below) as the sensor input and Caron Engineering’s signature analysis application to scan the cutting surface and determine if, and how much, that surface deviates from a Master Part or a nominal of zero.

The probe outputs measurement data at a rate of 1 sample per millisecond. This data rate allows high-speed scanning with high resolution results. The probe scans at feed rates of 600mm/min (25 in/min) and in some cases, even faster, with a resolution below 1um.

Probe Surface Scanning eliminates the need for multiple probe touch points, and multiple comparisons to the nominal. The probe relies on its own calibration, not the machine position, so the probe scanning won’t be affected by any machine setup errors.

Current system requirements include the Blum TC64 Digilog Probe, an RC66 receiver, IF20 interface and an EM33 module.

Key Features

- Provides rapid scanning of any surface that the scanning probe can access

- Displays on-screen analysis report after every scan

- In-process scanning and analysis optimizes process time

- Self-calibrating probe is resistant to machine setup errors

Products with Surface Scanning Capability

CNC Sensor Analysis System