Bar Feeder Vibration Detection Eliminates Scrap and Increases Spindle Life

Challenge

A customer has a Swiss-style lathe, running unattended, with an auto-fed bar feeder delivering 12-foot bar stock to the machine. This customer was scrapping a significant amount of parts due to irregularities in the bar causing dimensional and finish errors.

Solution

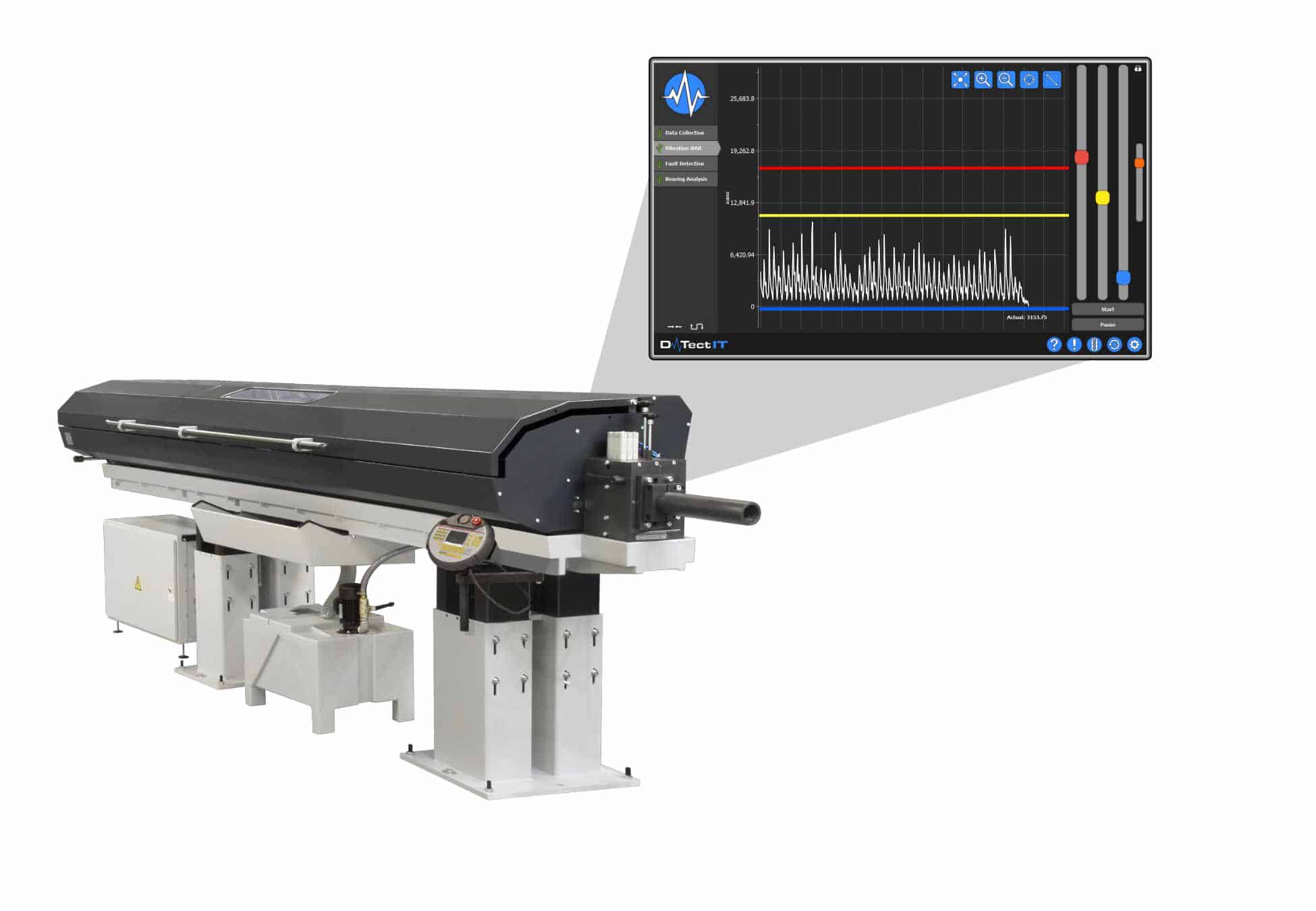

The customer mounted a Caron Engineering DTect-IT vibration sensor to the barfeeder and connected it to the Fanuc control to monitor certain characteristics of the lathe program. The customer set the vibration thresholds and then programmed an acceptable RPM range for compensation.

During machining, DTect-IT monitored the vibration levels on the barfeeder. If vibration was within the acceptable limits, nothing was changed. If vibration levels exceeded the userdefined limits, DTect-IT alerted the CNC control to reduce the spindle RPM within the acceptable range to compensate for the excessive vibration. DTect-IT then informed the CNC control when the vibration levels were (1) acceptable or (2) generated an alarm to stop the machine if the RPM had to be reduced beyond the lowest threshold to make good parts.

Using DTect-IT, the customer has eliminated scrap parts due to irregularities in the bar stock. Excessive bar feeder vibration also has a negative impact on bearing life. With DTect-IT monitoring the vibration, they have realized the additional benefit of increased spindle bearing life.

Results

- Eliminated scrap due to imperfections in material bar stock

- Improved spindle life by regulating vibration levels