Tool Monitoring System for Machining | TMAC

Integrating a tool monitoring system for machining is essential for protecting the machine, maximizing tool life, and reducing cycle time. Caron Engineering's adaptive tool monitoring system for machining, TMAC 3.0 (Tool Monitoring Adaptive Control), is a real-time tool wear and breakage detection system, with adaptive feed-rate control capability. Adaptive control with TMAC intuitively learns the optimum power for each tool and can maintain a constant tool load by automatically adjusting the feed rate during operation. TMAC interfaces directly with the CNC control and protects monitored machines and equipment by using high-precision sensor technology to optimize machining and make real-time corrective adjustments through material cutting. The data collected by the TMAC adaptive tool monitoring system provides detailed insights into the cutting process.

Caron Engineering’s tool monitoring system for machining TMAC can help you meet the demands of today’s competitive manufacturing environment and will improve overall performance, productivity, and profitability.

Optimize Machine Tool Cutting

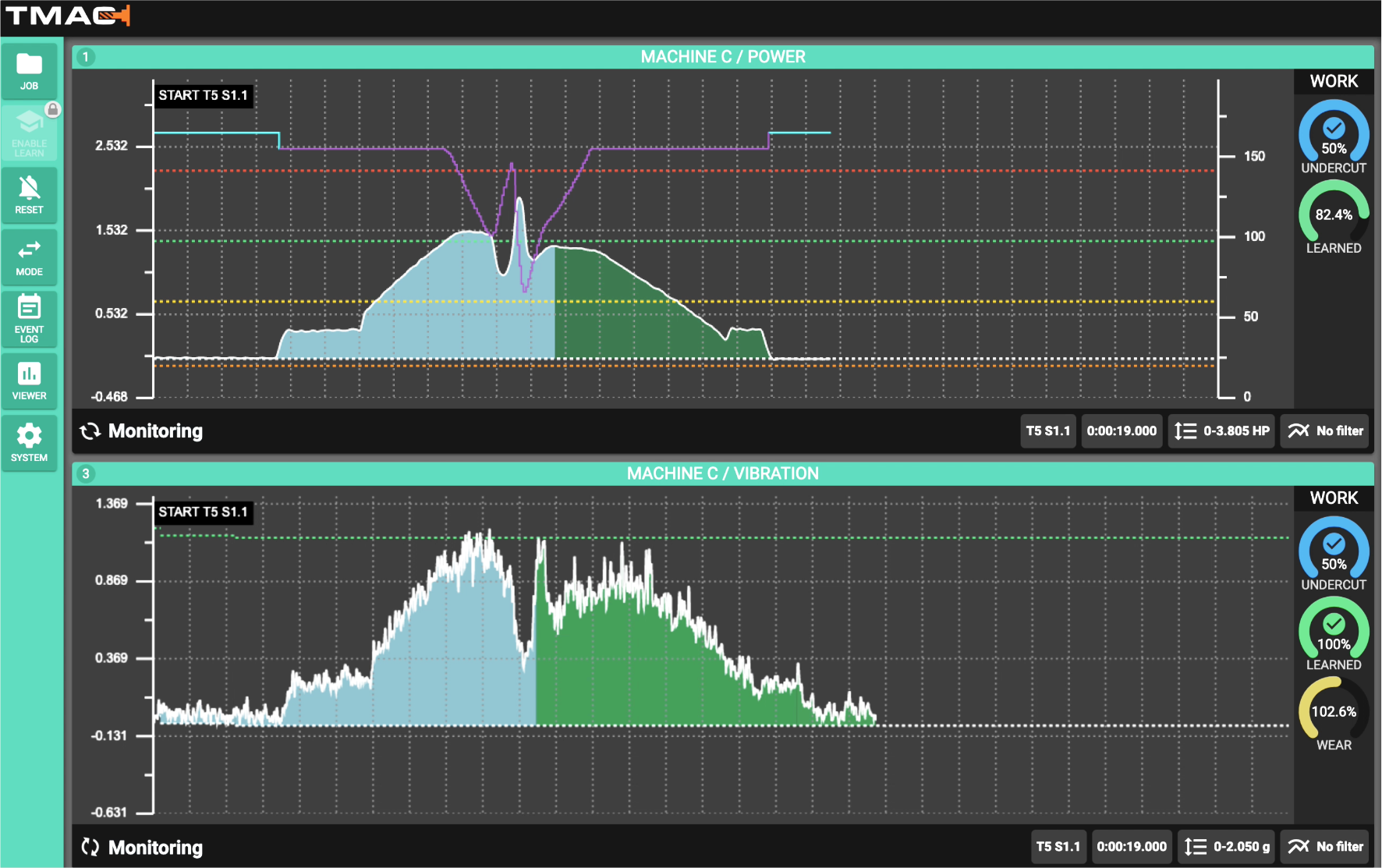

Caron Engineering's TMAC tool monitoring system for machining optimizes tool cutting with high-precision sensors, a dedicated high-speed data processor, and an intuitive human machine interface (HMI) to visually display tool wear and give real-time control over your cutting operations. TMAC utilizes a high-speed processor to coordinate all communication between the tool monitoring system, sensors, and the CNC control. The powerful processor can concurrently monitor multiple sensors, allowing TMAC to deliver results on complex machining challenges and provide immediate reaction to deviating conditions.

Optimize your cutting programs, maximize too life, and reduce cycle time with Caron Engineering's TMAC (Tool Monitoring Adaptive Control) System for CNC Machining!

By using the learned cutting data and defining thresholds, the TMAC tool monitoring system will calculate tool wear during cutting and automatically expire a tool when excessive wear is detected or issue a signal within 5 milliseconds to stop the machine and retract the tool in the event of breakage. By accurately monitoring tool wear in real-time you can prevent unplanned equipment downtime and stop potentially catastrophic events in their tracks.

This real-time control is ideal for achieving lighter and unattended operations.

Tool Wear and Breakage Detection

TMAC calculates power over time or work of the cutting tool as a more accurate measurement of how the tool is wearing over time

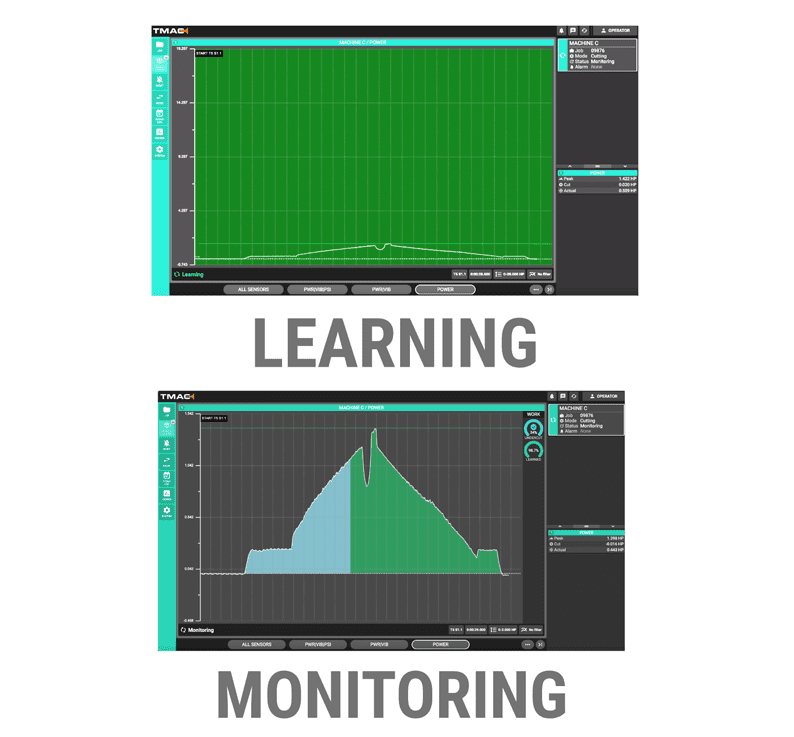

TMAC tool monitoring system measures tool wear and detects breakage by monitoring true spindle motor power. TMAC learns the optimum power for each tool and cutting section, and compares it to the user-defined limits to calculate wear in real-time as the tool is cutting. TMAC operates on the principle that the power required to cut a part increases as the tool’s cutting edges deteriorate, leading to increased costs, and potential for defective parts or equipment damage. TMAC determines tool wear and breakage detection through the following mechanisms:

- Monitors and reacts to tool wear in real-time

- Uses multi-range sensors with auto-scaling display sensitivity

- Prevents tool breakage and lowers scrap rate

- Reduces the cost of consumable tooling

- Provides valuable information about the cutting process

- Stops the machine instantly in the event of tool breakage

- Shows real-time data graphing as the tools are cutting

Adaptive Control Feed Rate Optimization

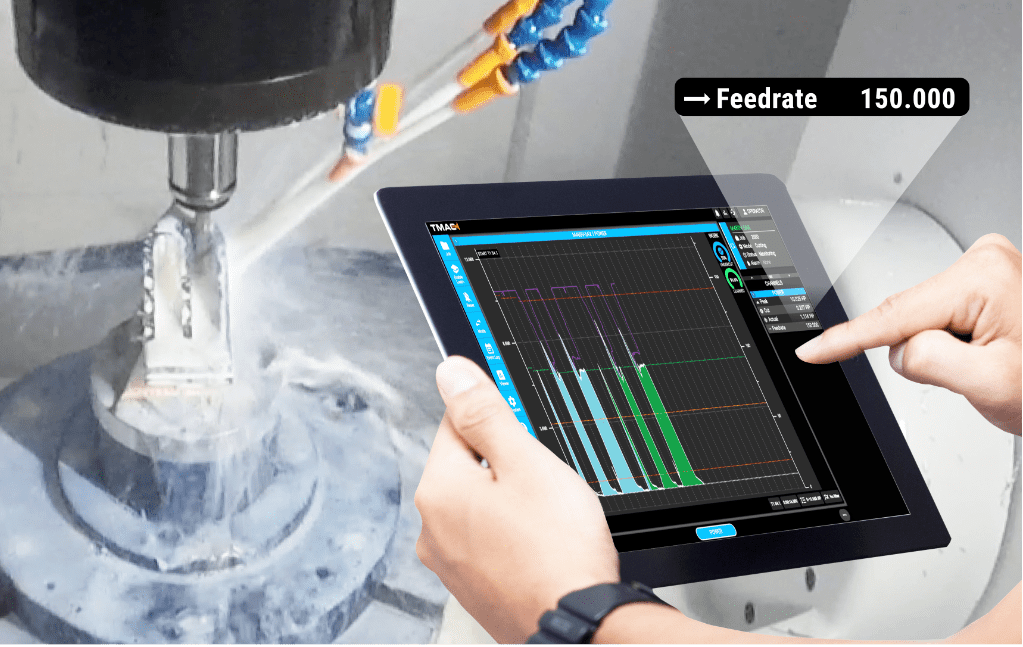

CNC machines are typically programmed for the safest feed rates to accommodate the worst machining and material conditions. With integrated adaptive control, the feed rate can be optimized depending on the spindle load, which regulates the feed automatically within set limits. This feed rate control delivers peak performance at all times and ensures your machines are pre-emptively protected from damage or catastrophic scenarios.

TMAC adaptive control learns the optimum power for each tool and continuously maintains a constant tool load by automatically adjusting the feed rate in real-time. TMAC increases the feed rate through low power cuts and decreases the feed rate through high power cuts and as tools wear. No operator intervention is required!

See how adaptive control technology works to automatically optimize feeds and speeds during cutting!

The result? Decreased cycle time, longer cutter life, and more machine uptime, especially with difficult to machine materials.

- Typical cycle time savings of 20 – 60%

- Allows tools to run at optimum feed rates

- Adjusts to variations in material, tooling, and depth of cut

- Excellent for unattended/lights-out operation

- Adjusts feed rates smoothly versus CAD/CAM programs that can only adjust per line in the program

- Calculates tooth pass frequency to adapt to low RPM cutters

Sensors and Components

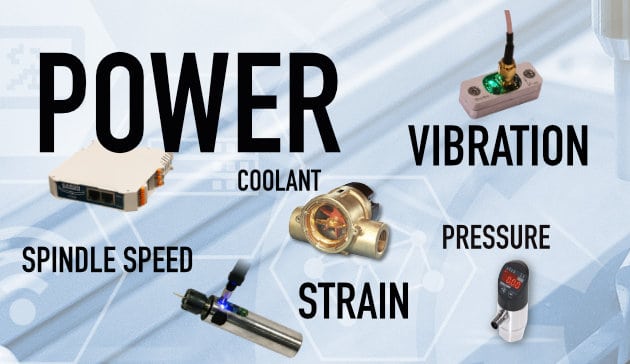

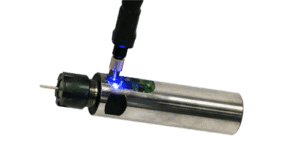

TMAC uses a dedicated high-speed data processor and has multiple integrated sensor options for total machine condition monitoring.

- TMAC 3-Phase multi-range power transducers measure the power load on the tool to determine wear

- Strain sensors embedded in a tool holder to measure force.

- Vibration sensors are capable of measuring vibration to 22 KHZ, with adjustable sensitivity. Vibration sensors also include a built-in temperature sensor.

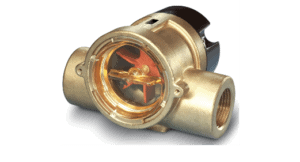

- Other peripheral sensors can be installed and monitored by TMAC including spindle speed, coolant flow, and coolant pressure

- GE P11TF12 Compliant

System Features

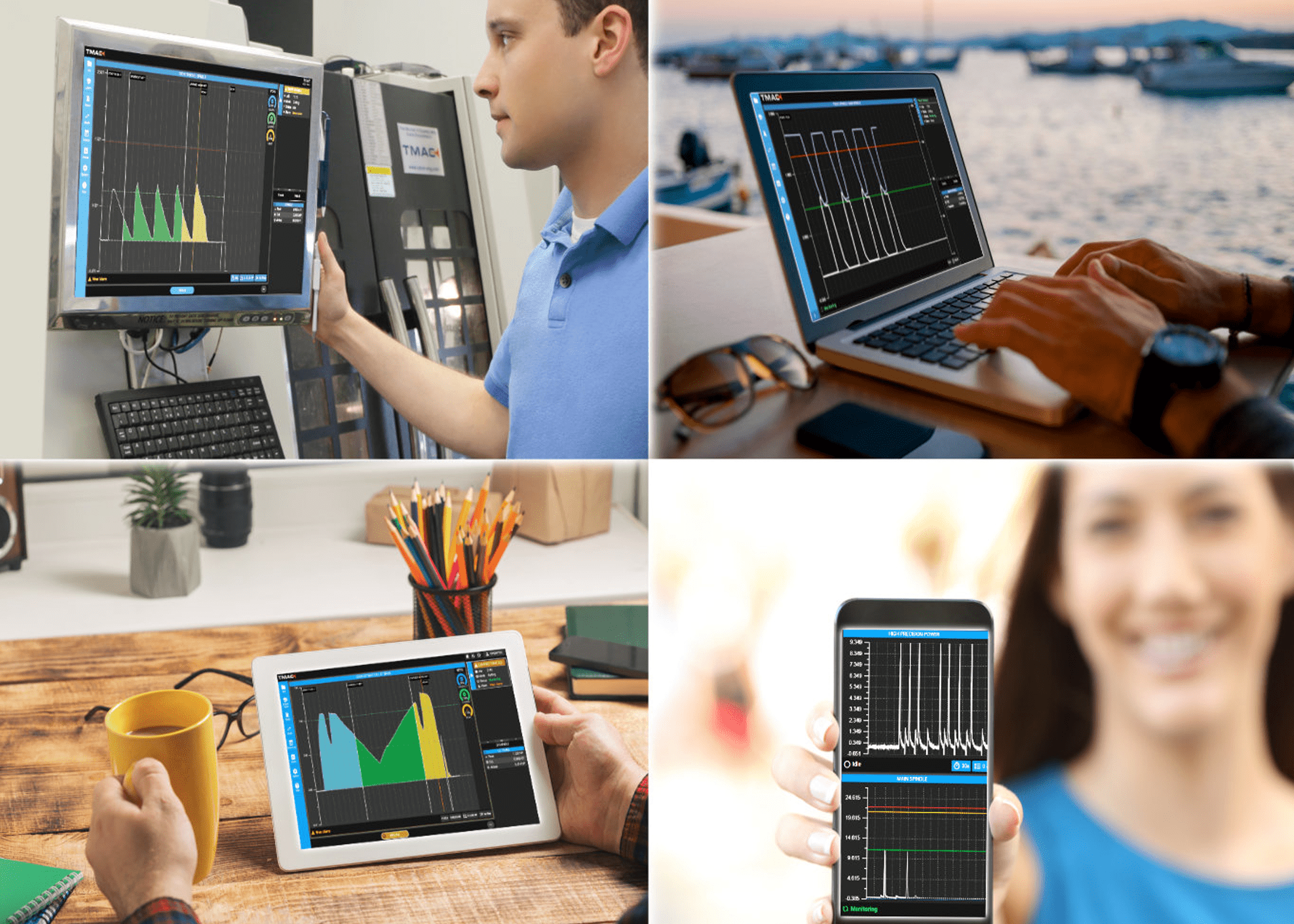

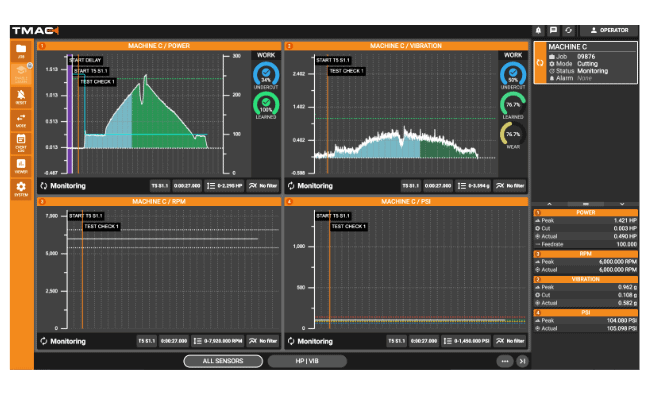

The advanced tool monitoring system, TMAC 3.0, offers an intuitive user interface designed to handle the complexity of the software while providing simplicity for the user. The web-based UI has completely customizable user views with a dynamic display that can be accessed from any device (including smartphones) and allows monitoring multiple processes and even multiple machine channels simultaneously.

Multiple sensor channels can be monitored simultaneously!

For instance, you can monitor power, vibration and coolant for a specific tool and section at the same time, and have unique limits for each sensor and channel.

- Create multiple custom views to look at monitoring data in different ways

- View up to 4 monitoring channels in a single view

- Toggle between custom views with the touch of a button

- Change background color to easily identify TMAC system

What Else Can TMAC Do?

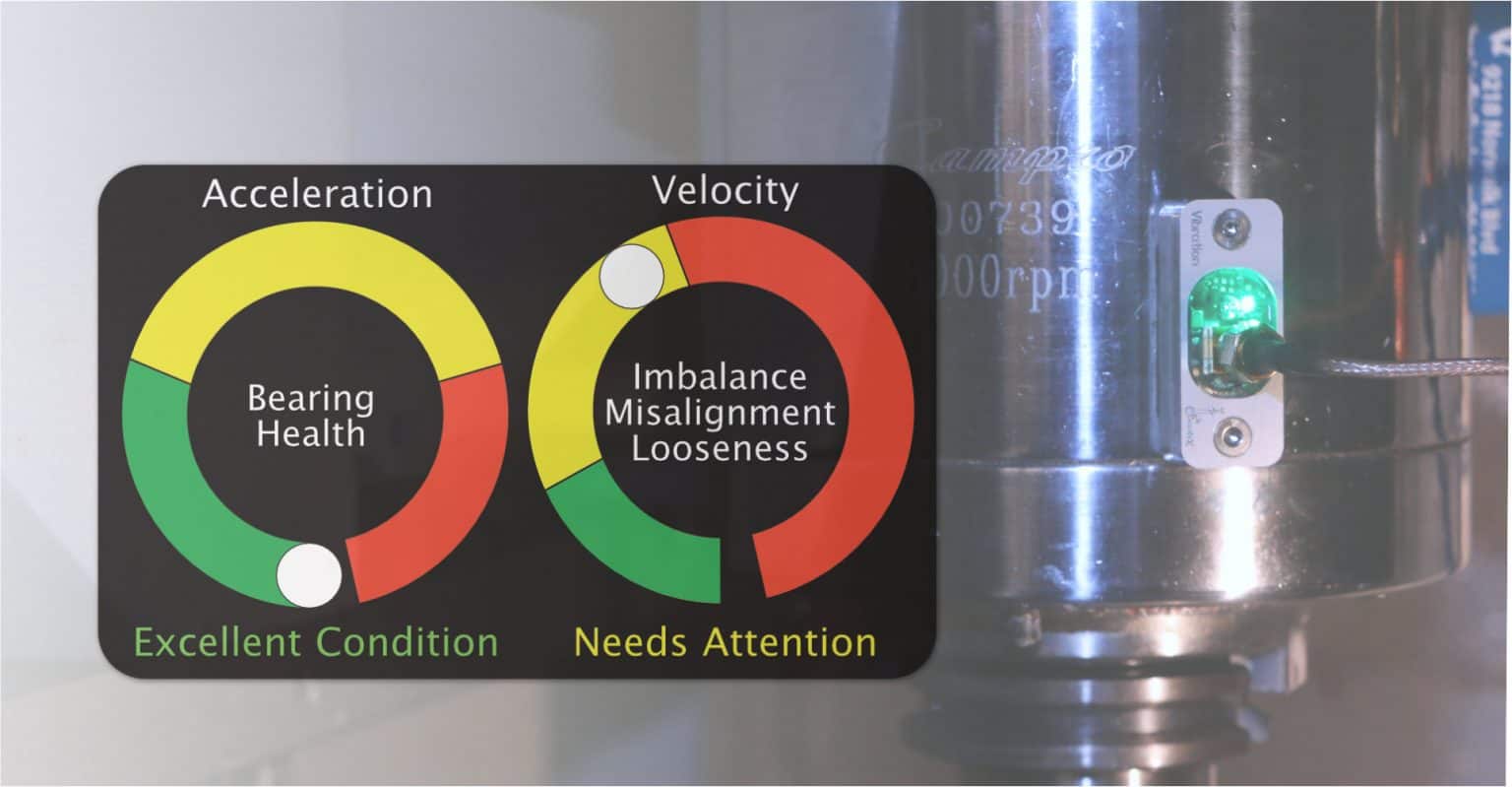

Spindle Bearing Analysis

A vibration sensor can be attached to the spindle, and hardwired directly to the TMAC tool monitoring system, with the bearing analysis initiated in the CNC part program. Spindle bearing analysis analyzes the vibration signal for acceleration to detect the health of the bearings and analyzes the velocity to detect any signs of misalignment, imbalance, or looseness that could result in defective parts or equipment damage.

Signature Analysis

Using the signature analysis mode, TMAC learns the entire path (signature) of a cut using any sensor type.

Data Analysis

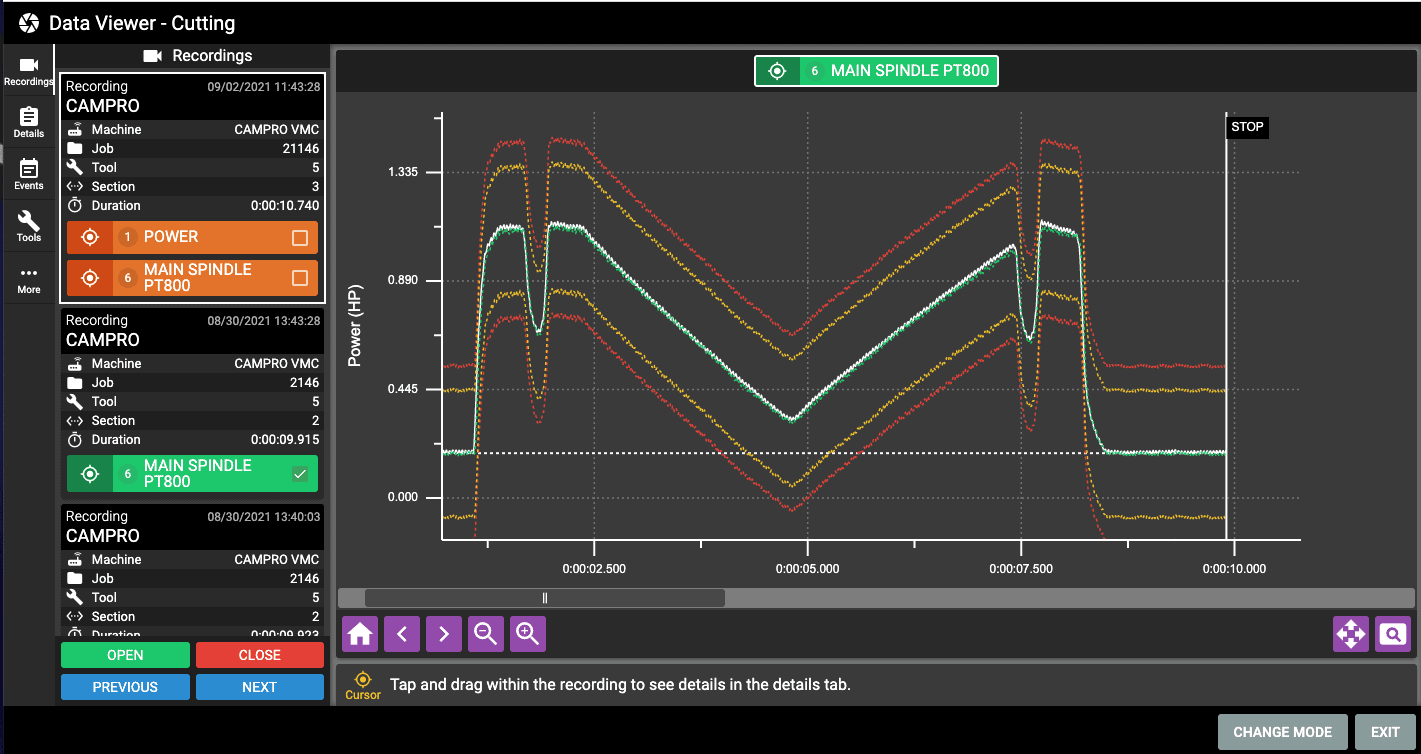

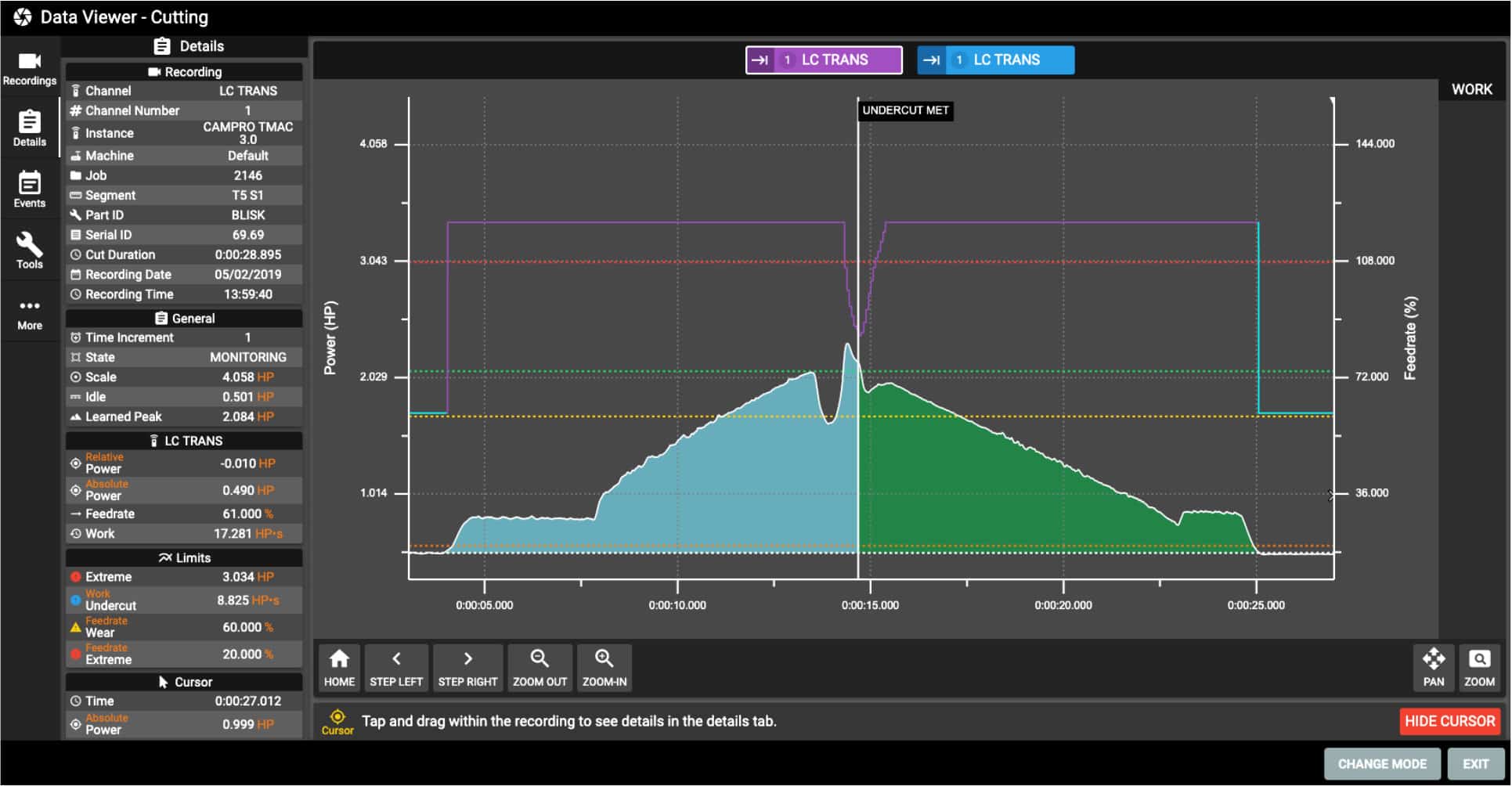

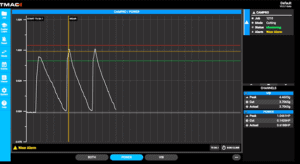

TMAC saves and records all cutting data in a singular place, providing an intuitive interface with multiple different viewing options. The TMAC Data Viewer displays monitored data and events that can be manipulated to different formats, cutting data files that can be overlaid to provide comparative analysis, and CNC positional information to allow user inspection of CNC axis positions or spindle RPMs. TMAC Event Viewer catalogs and displays critical event data like starts, stops, alarms, or custom points in the cutting operation. As a browser-based user interface, anyone connected to the integrated network can remotely view the data obtained through the tool monitoring system. This data allows the user to interrogate specific areas of the cut to look at anomalies in the normal cutting operation. If a tool uses inconsistent power over the same cut, the user can overlay these cuts to see what is causing any anomaly. This information can also give TMAC users insight into tool life comparison between different tooling vendors and regrinds.

TMAC Data Viewer

View the details of any cut, with pan and zoom options for a closer look!

- All monitored data and events are stored and can be exported in various formats for analysis

- Data files can be opened simultaneously to view graphical differences

- Cutting data files can be overlaid to compare cuts

- CNC position data allows the user to inspect the CNC axis positions, program line number, and spindle RPM to interrogate alarms and anomalies at any point in the cut

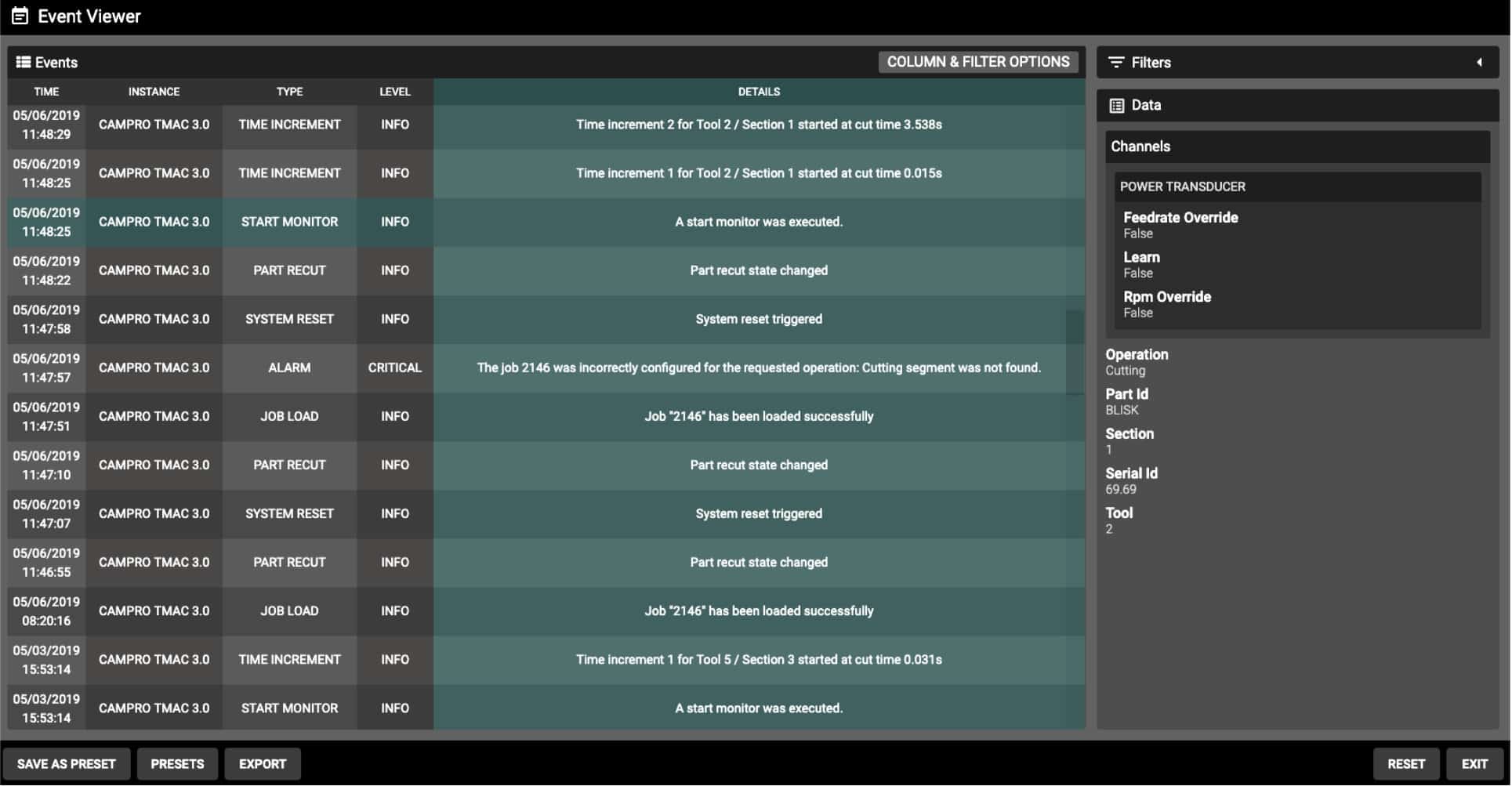

TMAC Event Viewer

Apply custom filters to view, sort, and export events for analysis.

- Displays detailed information for all events (starts, stops, alarms, etc.)

- Custom events can be created to call out specific points in the cutting operation

- Users can apply custom filters to view, sort, and export events for analysis

Production Monitoring Integration

TMAC data is seamlessly integrated into the Datanomix production monitoring platform to deliver deeper insights, giving you visibility from the tool to the machine to the overall factory. Learn more...

OnTakt Software from Wolfram Manufacturing Technologies enables machine shops of all sizes to easily connect machines in a single dashboard to capture TMAC data, visualize operations, and react on the shop floor. Learn more...

All Caron Engineering products include the MTConnect protocol communications which allows us to provide meaningful data to any supervisory software, for real-time data sharing.

VIBRATION

VIBRATION

COOLANT FLOW

COOLANT FLOW