Caron Engineering CNC Monitoring

Caron Engineering offers a unique product line of manufacturing technology that is extensive in its capabilities. The technology interfaces with nearly any CNC machine tool on the market, regardless of builder, with proven success optimizing productivity across all manufacturing sectors.

Introducing, MiConnect Technology! A flexible application builder used by our integration specialists to create custom automation and process control solutions that are unique to a manufacturer's operations. The graphical programming environment has pre-built drivers and operations to quickly build and execute CNC manufacturing projects.

Tool Monitoring Adaptive Control measures tool wear in real-time and uses adaptive control to automatically optimize feed rates through variations in material cutting; to maximize tool life and reduce cycle time.

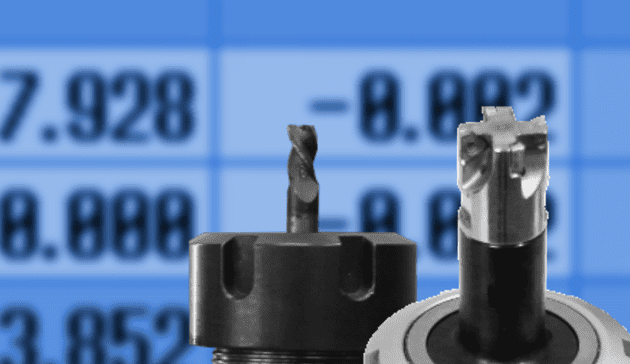

Completely customizable industrial tool identification and data management system; automating the transfer of tool presetter data to (and from) the machine CNC control via RFID tags in tool holders or 2D barcodes.

A PC-based software application that processes data from almost any electronic gauging device and automatically updates tool offsets in the CNC control. No manual data entry needed!

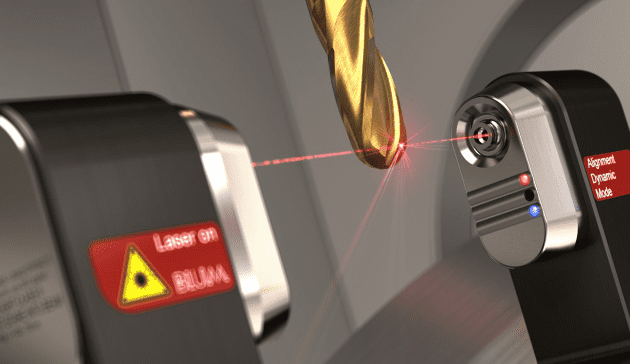

DTect-IT is a versatile CNC sensor analysis system that combines high precision sensor data with multiple analysis options to essentially monitor any area of concern on your CNC machine tool or fixture.

Fully customizable status lights for easy assessment of a part's progress, or any machine status indication.

In-Process Measuring and Testing Technology