Our smart technology products will automate and optimize your manufacturing before, during, and after cutting.

Caron Engineering's Wells, Maine headquarters has a showroom with multiple CNC machine tools equipped with all of their smart manufacturing solutions. If you would like to see any or all of these solutions in action, contact us to schedule an on-site visit or a virtual demo!

Introducing, MiConnect Technology!

The Next Generation of Manufacturing Automation Software

MiConnect Technology is a custom application builder, designed specifically for the CNC manufacturing environment, to streamline process automation and control. MiConnect has a growing inventory of pre-built drivers and operators, and a flexible flow-chart style design infrastructure that makes it easy for our integration specialists to create unique solutions for our customers in a fraction of the time!

We can use this technology to:

- Connect devices and operations on a shop floor

- Automate and simplify manufacturing processes

- Guide and verify operator interaction and process flow

- Data inter-change

- And, much more!

At Caron Engineering, we are in the business of helping manufacturers find solutions for all their machining challenges

ABOUT US

Since 1986, we are proud to be a leading provider of tool monitoring, automation, and process control systems for the manufacturing industry. Our growing product line of smart technology combines high-precision sensors with advanced monitoring capability to reduce cycle times, promote unattended operation, eliminate human-error, drive down tooling costs, and minimize expensive damage to machines and work-holding.

As an employee-owned company (ESOP), we believe in building strong relationships with each other, our customers, and the community. We are driven by our passion to continuously improve manufacturing processes and increase productivity. We strive to be the best at what we do and pride ourselves on our ability to deliver world-class products that are innovative, reliable, and easy to use.

Our Solutions Enable Lights-Out Machining

Caron Engineering Featured Solutions

Our products incorporate a wealth of capabilities to increase performance, productivity, and profitability for all manufacturing industries.

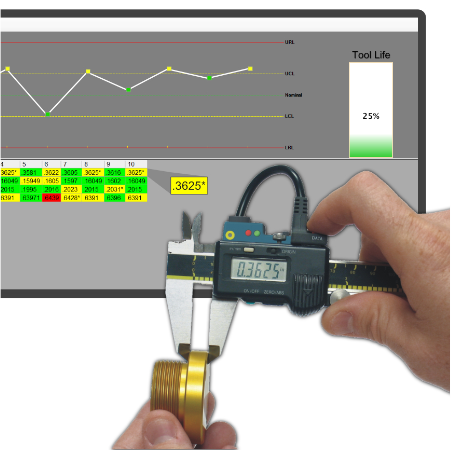

THE RESULTS

Check out the results our customers are seeing by implementing Caron Engineering technology to optimize their manufacturing operations.

WHAT'S NEW AT CARON ENGINEERING?

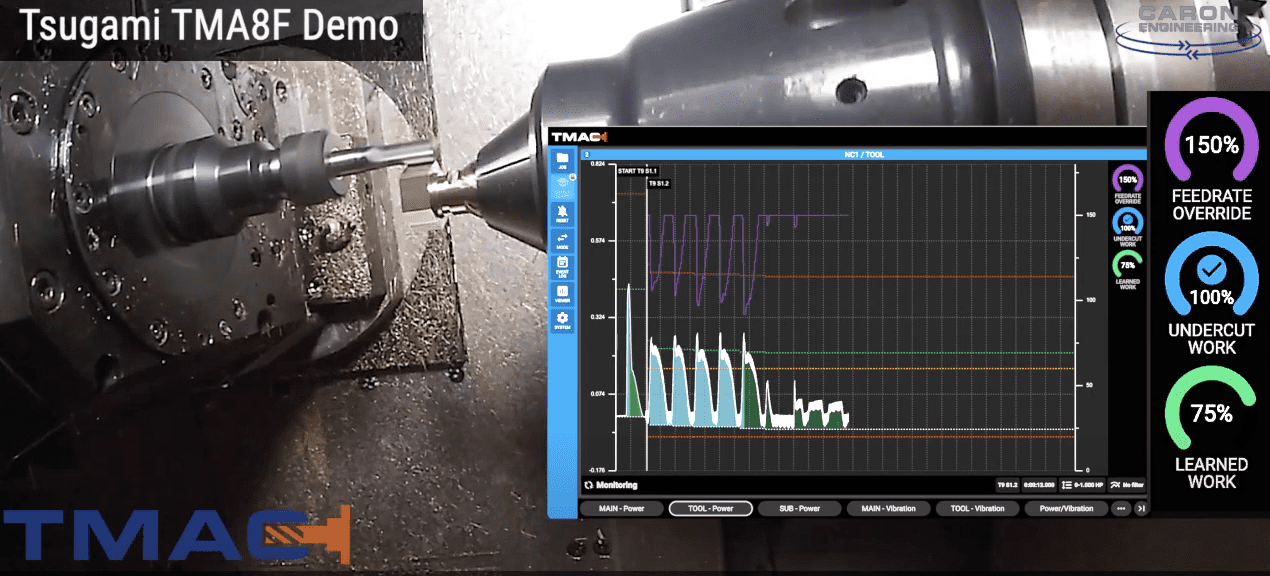

Caron Engineering Featured the Latest Technologies for Automation and Process Control at EASTEC 2023.

In case you missed it, Caron Engineering had their newest monitoring, automation, and process control technologies for manufacturing outfitted on a Tsugami SS327-5AX for a fully automated machining demonstration in booth 5359 at EASTEC 2023.

Combined with partner technology, they demonstrated seamless automation for fully unattended machining. Check out the highlight video to see all the integrated technology.

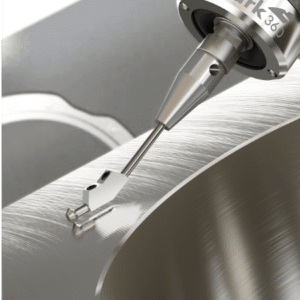

In-Process Surface Roughness Analysis for CNC Machined Parts

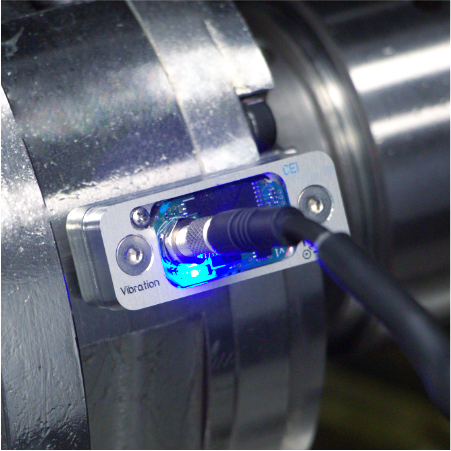

Caron Engineering has added in-process surface roughness measurement to the suite of applications for their DTect-IT product.

DTect-IT is a versatile CNC sensor analysis system that takes in data from a multitude of high-precision sensors. The surface roughness measurement application uses the Blum-Novotest TC64 RG Digilog Probe as the sensor input in DTect-IT to analyze the surface of a part.