TMAC Cuts Scrap Rate by Monitoring and Detecting Breakage on a .030″ Drill

Challenge

The end user was using a Swiss-style automatic lathe CNC to drill many super small .030” holes. Their intention was to run a continuous process with unattended (lights-out) operations.

Due to the hardness of the titanium part and the smallness of the tool, drills would often break unnoticed, and subsequent parts would be “completed” with missing holes until noticed by a human operator many hours later. This caused an unacceptable scrap rate.

Solution

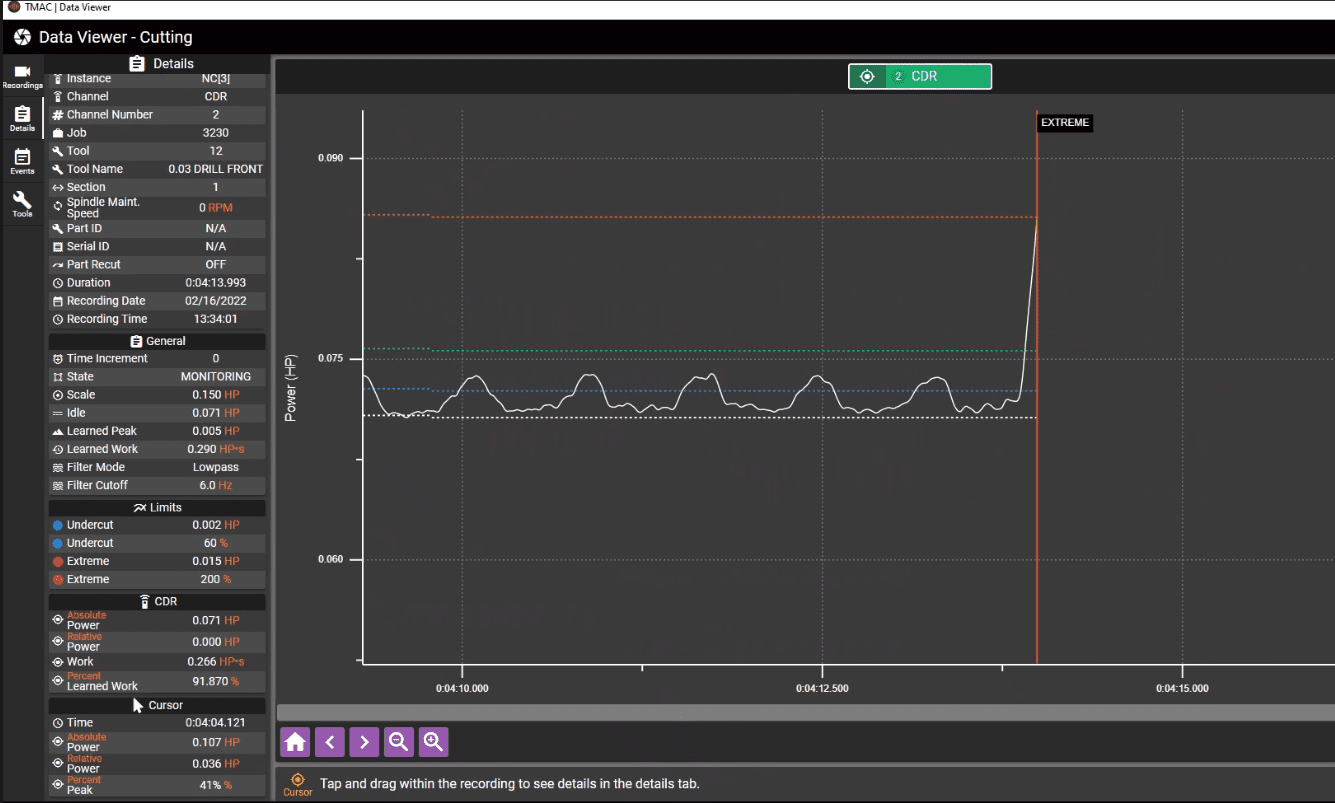

Caron Engineering installed a TMAC system with three PT800 power sensors to measure the power load used by the main spindle, power used by the 0.030” drill spindle and one for the 0.055” drill spindle. Based on learned limits, TMAC was able to determine when the tool was not cutting but should have been (i.e., broken). To do this, TMAC compares the learned cutting power to the user defined limits to detect when too much or not enough power is achieved.

When the limit is exceeded, TMAC alarms and immediately stops the process within 5 milliseconds, and retracts the tooling.

At a glance the operator can determine which tool was broken, replace that broken tool, and restart the process. This gave the customer the ability to run the machine with little to no supervision, while producing very little scrap.

Results

- Reduced scrap and decreased cycle time

- Allowed the process to run with little to no operator supervision

TMAC Data Viewer – shows

successfully drilled holes with the

last one generating an extreme

alarm indicating tool breakage