Machine Tool Sensors

The DTect-IT Sensor Analysis System combines high-precision machine tool sensors with advanced analysis capability to detect and (depending on the application), correct anomalies occurring in the machining process. Using a multitude of machine tool sensor options, the user can monitor specific parameters to alarm and signal the CNC when irregularities are present. DTect-IT applications can range from monitoring high-resolution power to detect tool wear and breakage, to monitoring spindle bearing health using vibration analysis, and even detecting surface roughness using a Digilog probe sensor input. Plus, with the advanced historical viewer, all machine tool sensor and monitoring data is recorded and accessible to analyze, compare, and trend data over time.

System Overview

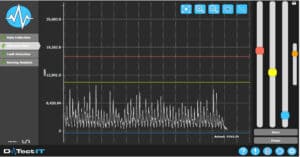

The DTect-IT CNC Sensor Analysis System has an intuitive user interface with a graphical display that allows you to view the real-time sensor and monitoring data, and easily toggle between analyses with the click of a button.

- Operates on any Windows PC with an available USB Port

- Runs standalone or easily integrates with the CNC control

- Multiple analyses can run simultaneously from a single sensor

- Graphing and monitoring can be initialized from the user interface or the CNC control

- Ideal for monitoring up to 4 tools

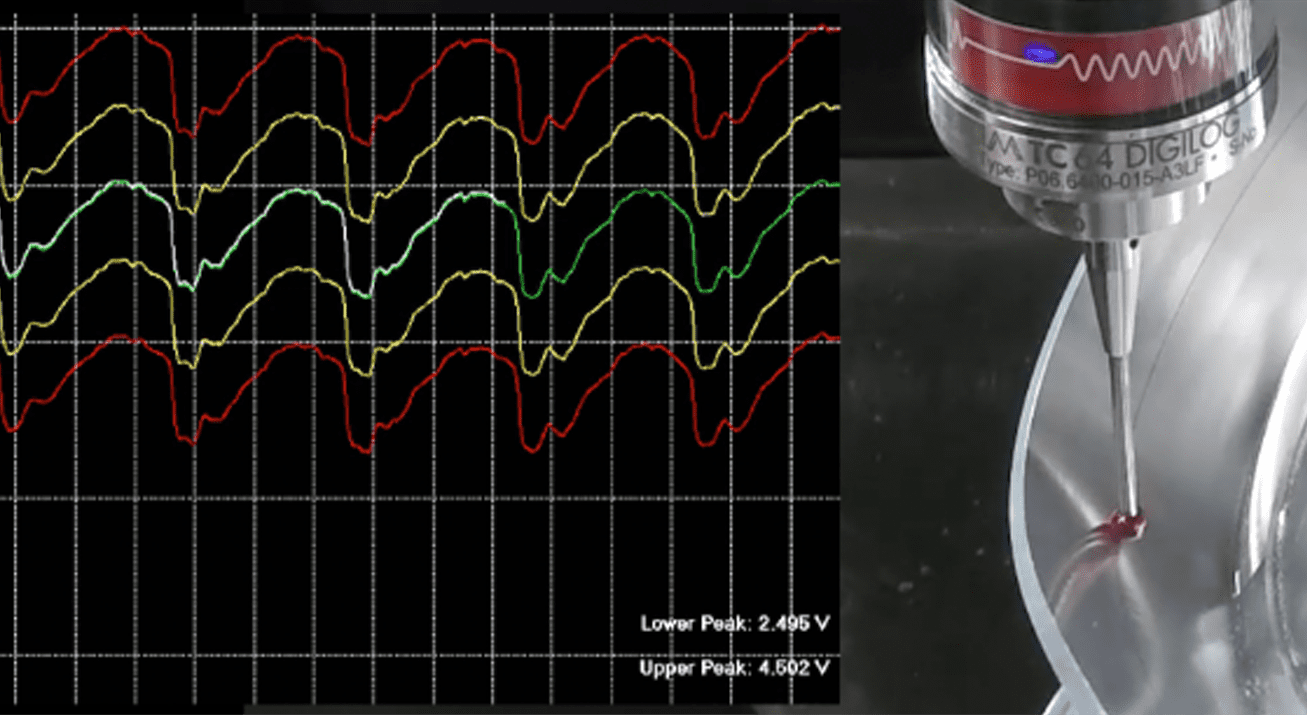

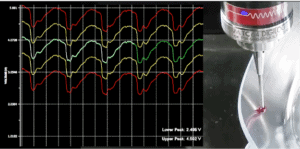

Spindle Vibration Monitoring

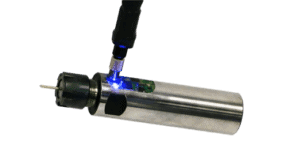

DTect-IT works with multiple machine tool sensors, including:

- Vibration

- Strain

- Power

- Analog

- Roughness Gauge

- Scanning Probe

- Audio

A single sensor can be set up to run multiple analyses.

Sensor Specifications

Analysis Types

The various analysis types allow the user to analyze their CNC machine and interrogate sensor data on multiple levels.

Analysis types include:

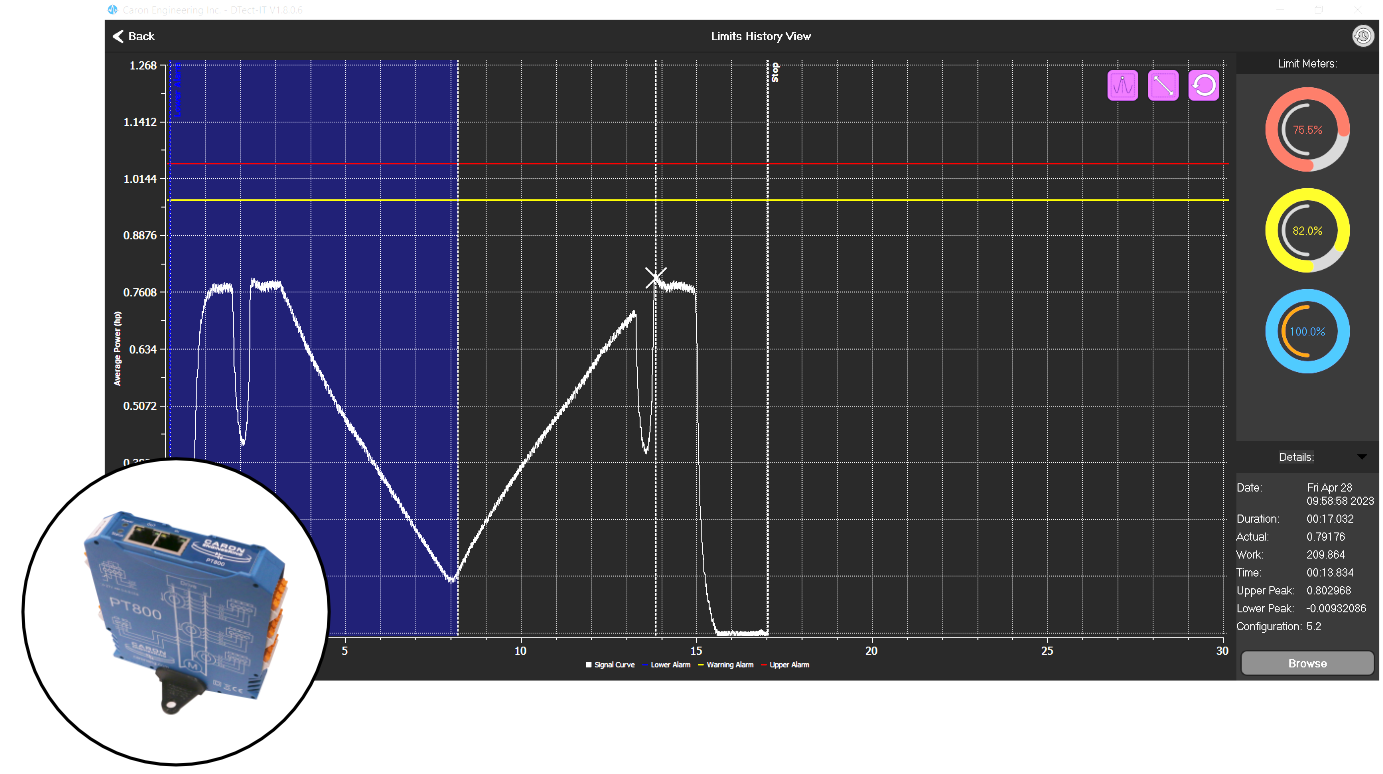

- Limit Analysis

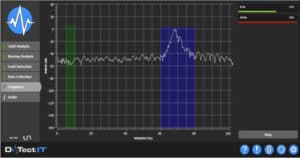

- Spindle Bearing Analysis

- Fault Detection

- Frequency Analysis

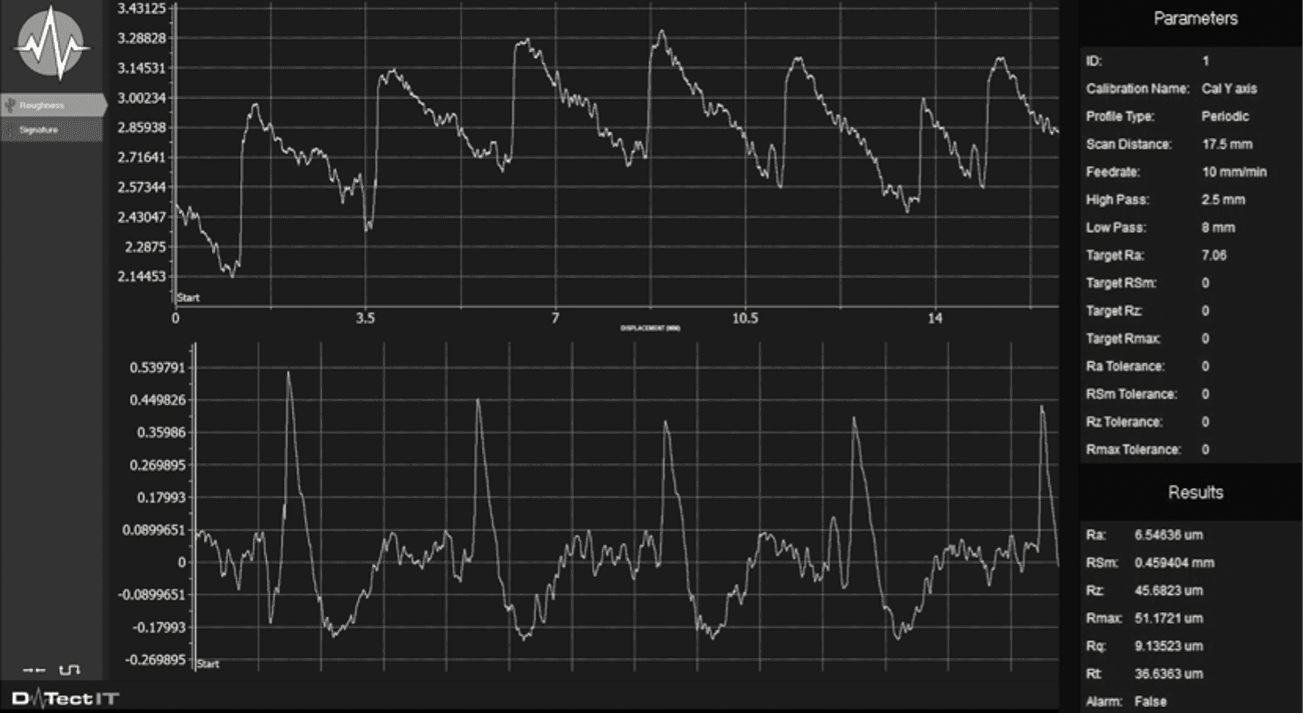

- Signature Analysis

- Data Collection Analysis

DTect-IT Applications

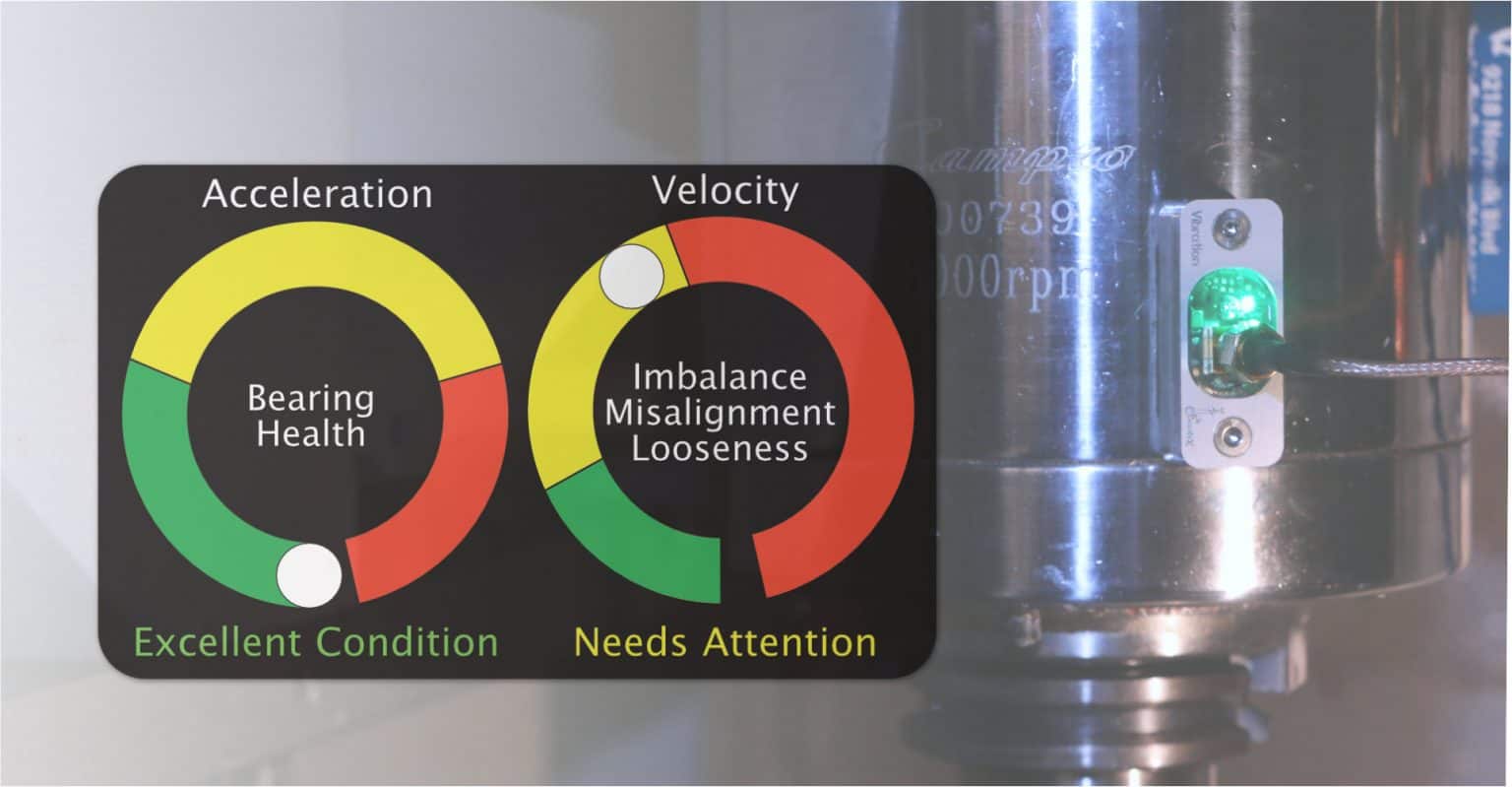

Bearing Analysis

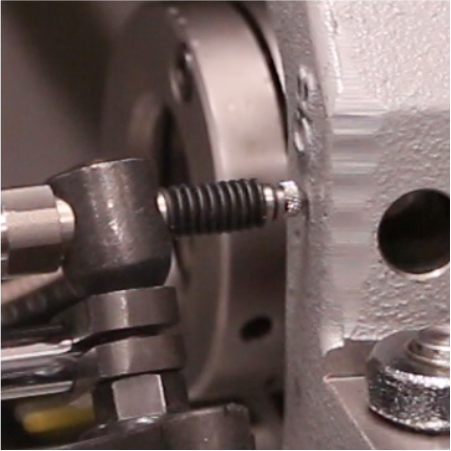

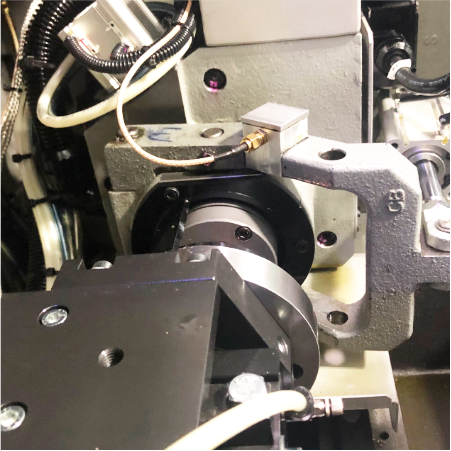

Using a vibration sensor attached to the spindle, DTect-IT can accurately assess the health of the spindle bearings.

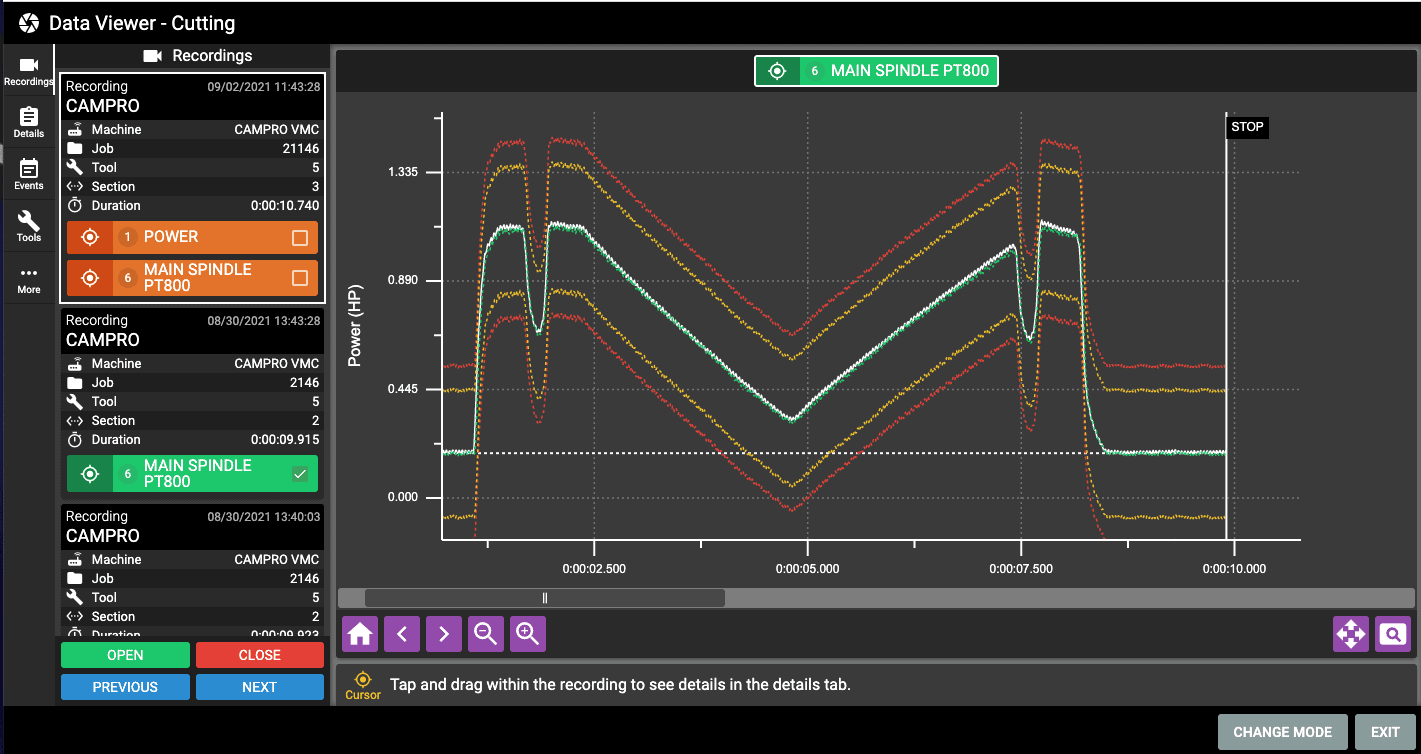

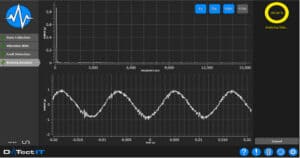

Signature Analysis

Using the signature analysis mode, DTect-IT learns the entire path (signature) of a cut using any sensor type.

Surface Roughness Detection

Probe Surface Scanning

Other Prominent Applications

Bar Feeder Vibration Detection

Eliminate scrap and reduce spindle damage due to excessive vibration!

- When excessive bar feeder vibration levels are detected, DTect-IT will automatically signal the CNC to reduce spindle RPM until the vibration levels are acceptable to make good parts

- If RPM has to be reduced too much and parts cannot be cut, an alarm can be generated to inform the operator to stop the machine and remove the bar

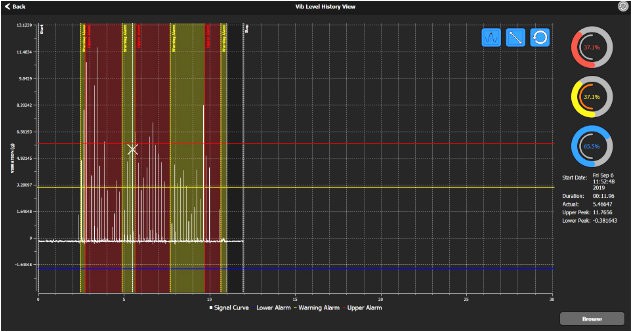

Data Viewer

All monitored data is stored and can be accessed via the DTect-IT Viewer for inspection, review, and analysis.

- View chart files

- Trend sensor data over time for predictive maintenance

- Export data for advanced analysis

Technical Specifications

All Caron Engineering products include the MTConnect protocol communications which allows us to provide meaningful data to any supervisory software, for real-time data sharing.

VIBRATION SENSOR (Wireless and USB Options)

VIBRATION SENSOR (Wireless and USB Options)

Analog Sensor

Analog Sensor

System Requirements

System Requirements Compatible Controls

Compatible Controls Stored Data Format

Stored Data Format Available Communication

Available Communication