DTect-IT Monitors Tool Wear and Breakage of a 2.7mm Drill and 3.05mm Reamer

Challenge

This automotive manufacturer was using a competitor’s product to try and monitor a very small drill and reamer cutting cast aluminum. They noticed the monitoring system was slowing the process and adding several seconds to the cycle time for every part.

Solution

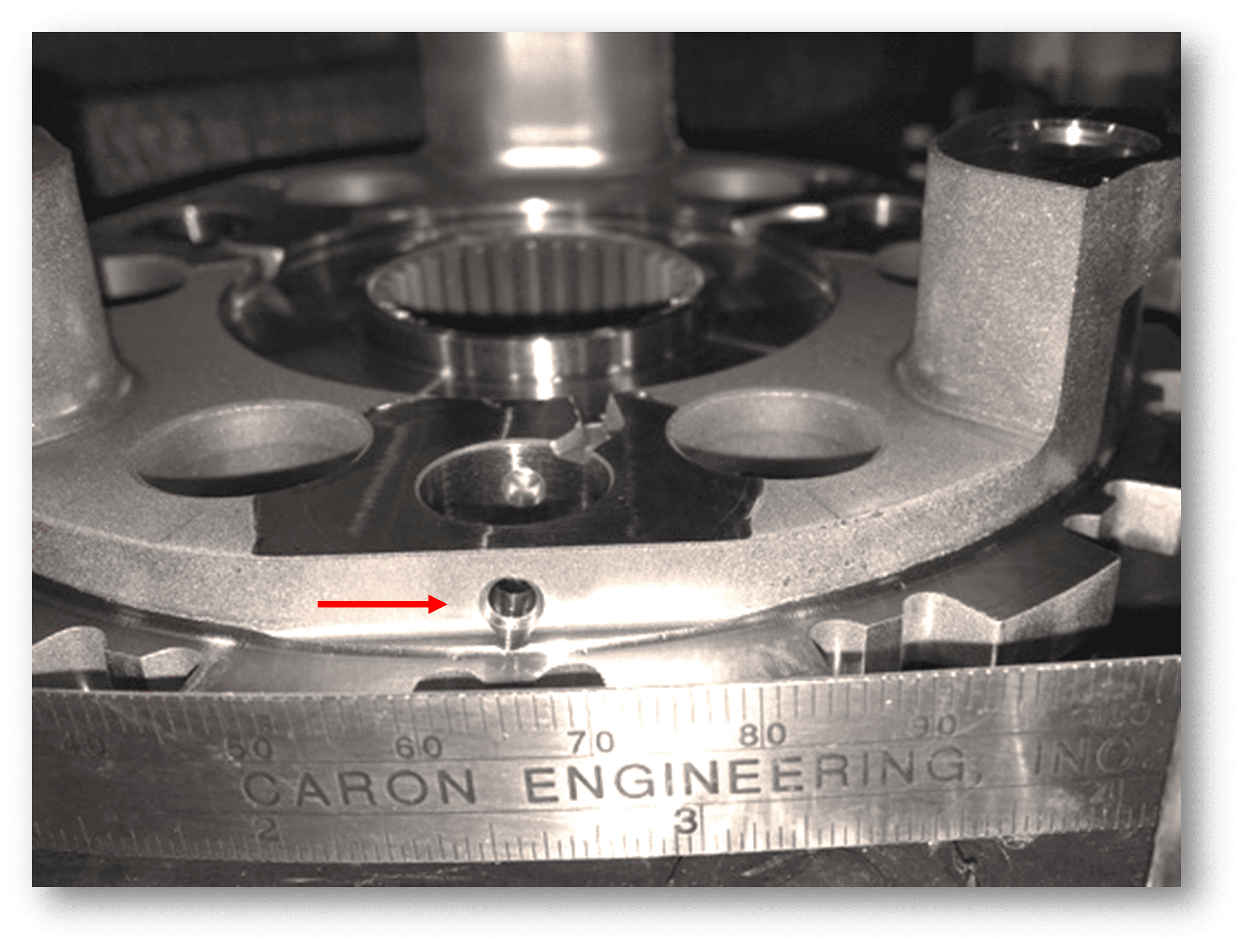

The customer needed a better solution, so they implemented Caron Engineering’s versatile sensor analysis system, DTect-IT. Using DTect-IT the customer is now successfully monitoring breakage and wear on the drill and reamer that create this hole (pictured right).

For this application, DTect-IT uses a high precision power sensor to measure the cutting loads of the 2.7mm drill and 3.05mm precision reamer, (with the reamer enlarging the hole by .08mm).

DTect-IT is efficiently identifying broken, missing, and worn tools with no negative impact on the part cycle time.

Results

- Successfully detecting broken, missing, and worn micro-tools

- No additional cycle time was added using real-time monitoring