TMAC Saves $300K per Month for this Automotive Customer Machining Camshafts

Challenge

A customer manufacturing camshafts for the automotive industry needed a solution for a very costly problem. Operators were loading tools incorrectly and failing to replace broken tools. Consequently, a necessary oil drain hole was not getting machined through the camshaft, leading to engine failures. Due to the repeated failure, this company was mandated to have all camshafts inspected by a 3rd party. This was costing them an additional $300,000 per month.

Solution

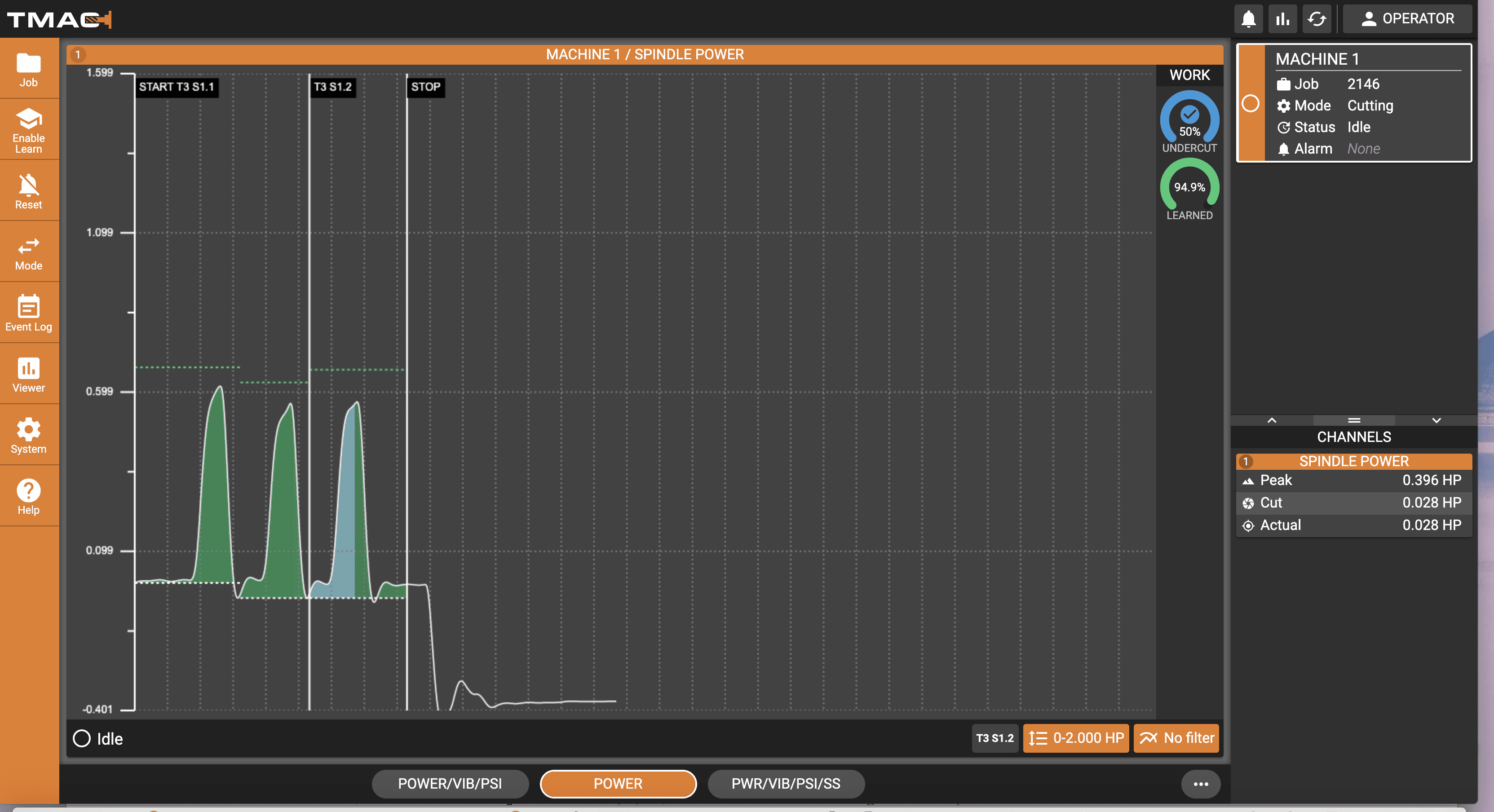

The customer implemented Caron Engineering’s TMAC system. TMAC is an advanced tool monitoring system that first learns the optimum power for each tool in cut and then compares it to user-defined parameters (limits) to monitor the cutting tools in real-time.

By setting an undercut limit with TMAC, they were able to detect if the hole was actually being machined. The undercut limit is used to detect if not enough power is achieved based on the learned cutting data. In this case, not enough power indicated that the hole was not machined completely, and an alarm would alert the operator.

In addition, a TMAC extreme alarm was set to alert the operator if a tool was broken. TMAC was able to safeguard the process to eliminate the operator error associated with tool loading and broken tools.

By increasing process confidence, TMAC removed the need for the additional 3rd party inspection, resulting in substantial monthly cost savings.

Results

- Reduced costs by $300K/monthly by eliminating 3rd party inspection services

- Eliminated operator errors to increase process confidence

TMAC monitoring shows the undercut

limit satisfied indicating the hole was

drilled successfully