In-Process Inspection Plays a Key Roll in Productivity Increases for this Customer

Challenge

The customer wanted a fully automated work cell, with a goal of increasing productivity by 50%.

Solution

The company implemented multiple systems to increase productivity by 200%. One of these systems being Caron Engineering’s AutoComp software.

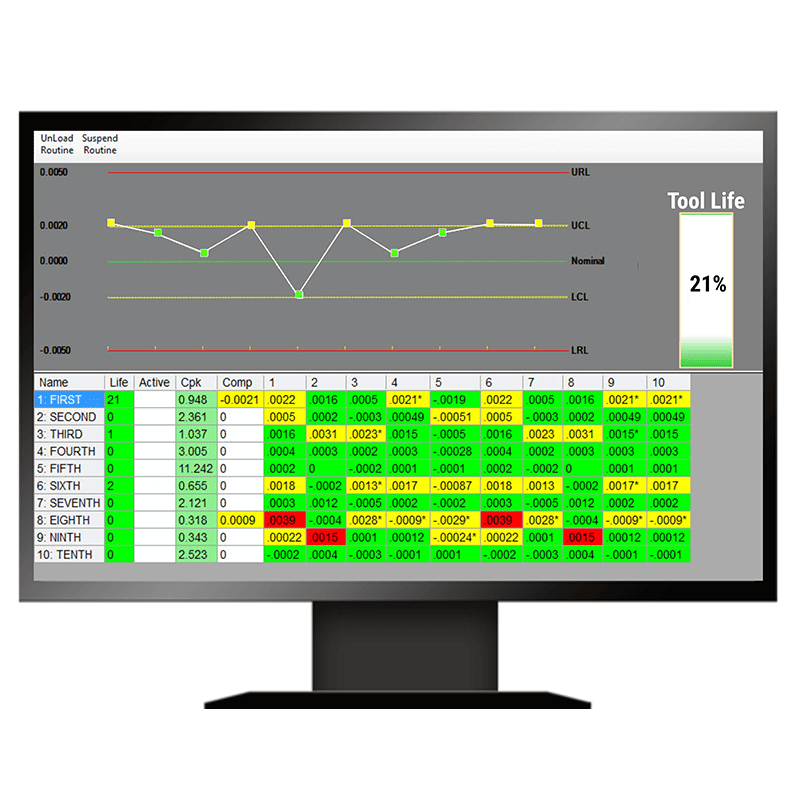

“The automated cell uses in-process inspection, which saves the company both time and labor costs. The robot performs a thorough inspection process for quality control purposes, taking the last part to be placed in a tray through an ultrasonic wash station, then to a CMM for inner-diameter measurement and a laser-profile inspection machine for outer-diameter measurement.

The data is processed by Caron Engineering’s AutoComp Software and fed back to the producing machine to enable tool-wear compensation that maintains part accuracy. Software-driven inspection data for automatic tool offsets eliminates human error, thus improving product quality and reducing scrap.”

Results

- Increased productivity by 200% using automation technology including Caron Engineering’s AutoComp Software

The AutoComp display shows the

measurement data for each

dimension and tool life.