Machine Tool Data Management System

ToolConnect eliminates human error and reduces setup time by automating the transfer of tool presetter data to (and from) the CNC control.

ToolConnect reads and processes RFID and 2D barcode data and updates offsets automatically; no operator data-entry or interaction with the CNC control needed!

Each ToolConnect system is uniquely configured to meet the customer’s requirements and tool load process specifications.

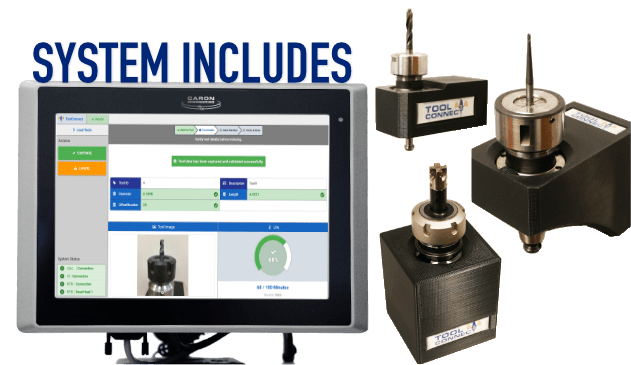

ToolConnect: RFID System

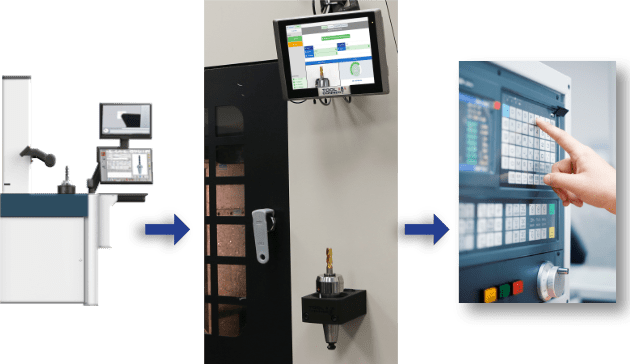

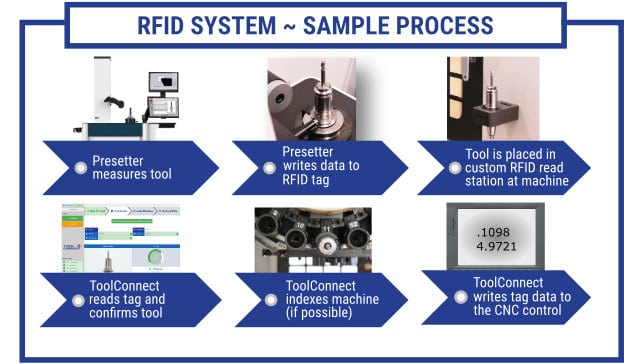

The ToolConnect RFID System automatically transfers tool presetter measurement data directly to and from the CNC control via RFID tags embedded in tool holders.

- Tools are measured at the presetter where tool data is written to the RFID tag

- The tool is placed in a custom RFID read station at or inside the CNC machine and all tool data is read and processed by ToolConnect

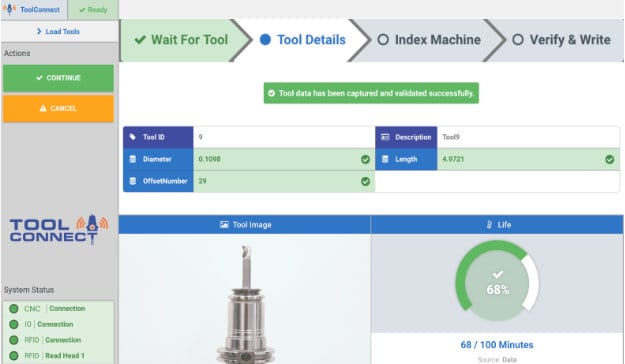

- The ToolConnect user-interface guides the user through the required (customer-defined) steps and confirms successful completion before allowing the user to proceed to the next step

- ToolConnect reads and writes data to the CNC control; automatically updating tool offsets and tool life data to (and from) the RFID tag

RFID System Includes:

- ToolConnect software

- A custom-designed tool pot (read station) for the proper tool holder type

- A tool ID controller with read/write head

- An 8″ touch screen PC for user prompts and information

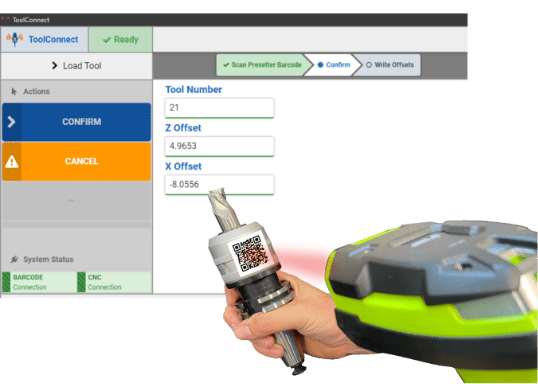

ToolConnect: 2D Barcode Scanning System

The ToolConnect 2D Barcode Scanning System automatically transfers tool presetter measurement data directly to the correct fields in the CNC control via 2D (presetter) printed barcode tags.

- Tools are measured at the presetter where the tool data is printed to a barcode tag

- 2D barcode scanner scans the barcode at the machine

- ToolConnect processes and displays the scanned data

- ToolConnect guides the user through the required tool load steps and updates tool and offset information in the control automatically

2D Barcode System Includes:

- ToolConnect software

- 2D barcode scanner

- An 8″ touch screen PC for user prompts and information

Benefits

- Automates the process of loading and unloading tools

- Reduces setup time and improves productivity

- Ensures consistent and accurate process flow

- Eliminates operator errors by automatically updating offsets in the control

- Verifies the correct tool is being loaded into the machine

- Provides a common user-interface for every CNC machine on the shop floor

- Eliminates the need for a post-processor

- Maximizes chip cutting time by using offline tool setting

System Features

- Works with nearly any presetter that can write to an RFID tag or print a 2D barcode

- Easily integrates with almost any machine and control type

- Intuitive operator screens display all tool information and guide the user through the process flow, ensuring each step is successfully completed

- The flexible design of the software can easily accommodate changes to the process

- MTConnect Compliant

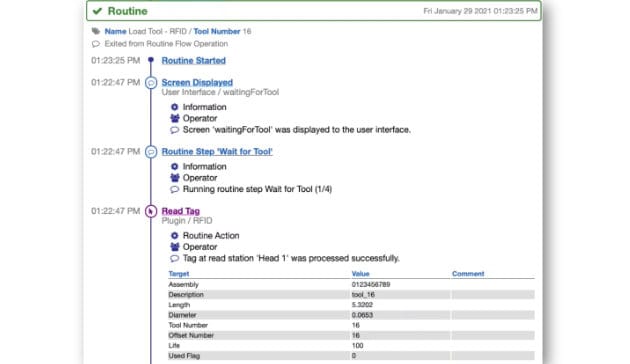

THE DATA: ToolConnect Audit Log

- Every step, action, and data exchange is logged with date and time stamp

- Data is available locally or via MTConnect

- This data is valuable for quality control and process verification

Customized Process Flow

The guided process flow is unique to the user’s tool load specifications.

- Prompts the user through the process flow

- Forces and verifies steps

- Will not let the incorrect tool be loaded

- Sends data directly to the CNC control

Standard Control Interface

- Fanuc (Focas ½)

- Okuma P controls

- Heidenhain

- Mitsubishi

- Siemens 840D

- Mazak

- Fagor

- Makino

- Brother

- Haas

All Caron Engineering products include the MTConnect protocol communications which allows us to provide meaningful data to any supervisory software, for real-time data sharing.