How to Reduce Machine Tool Setup Time

Challenge

This customer has 6 identical vertical machining centers running the same part, so each machine has identical tooling. The biggest issue was operators moving tools from one machine to another (all machines are identical & making identical parts). When the operators noticed a tool had worn from one machine, they would just pull an identical tool from another machine, since the tool carousel is openly accessible. So, there was no accountability of the tools.

In addition, the operators would not always take the time to get the tool information (geometry/wear/life) from the previous machine to the new machine which induces error into the process. In the rare cases when they did take the time to get the tool information, it caused downtime and was subject to fatfinger errors.

Solution

By implementing Caron Engineering’s ToolConnect RFID system, it is now impossible to cut if the wrong tool is in the machine without updating the necessary tool parameters, since the information travels with the tool.

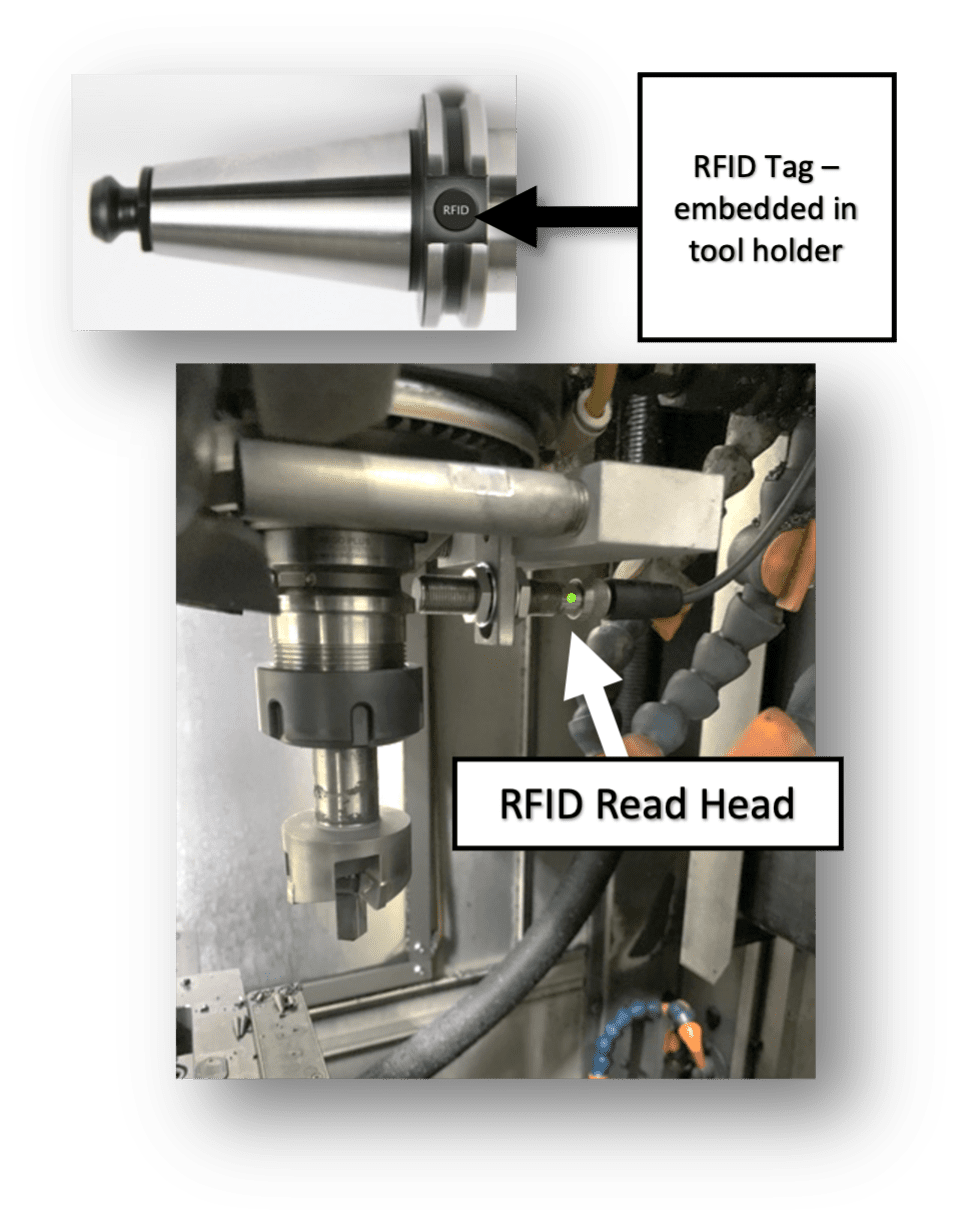

The ToolConnect system uses embedded RFID tags inside the tool holders. Each tag is written at the presetter and contains all the data for the specific tool, including geometry, wear, and tool life information.

There is a file in ToolConnect that defines acceptable tolerances for each tool. ToolConnect will recognize if the wrong tool is in position and will not allow the process to continue. For this unique ToolConnect system, all of the transactions occur while the tool is in the spindle. Tools are read/written per the below (system overview) specifications after insertion and prior to removal from the spindle.

The tool is measured by a laser in the machine, and tool offsets are updated directly to the wear table in the CNC. ToolConnect reads the wear table and updates the tag the next time the tool is in spindle position.

The entire process is automated. If tools are used across multiple machines, the required tool data is transferred with the tool. No operator data entry is required.

System Overview – Specifications

Tool READ/WRITE Description: Tool status bit = NEW

Tool READ/WRITE Description: Tool status bit = NEW

1) Tool pot value on tag is compared to tool pot in which tool resides. If not corresponding, then an alarm is generated.

2) If tool pot values coincide then the tool geometry data on the tag is written into the CNC tool geometry table and the CNC wear table is set to 0.

3) The used tool life will be set to 0.

4) The tool status bit is set to used.

5) The machine ID will be programmed onto the tag.

Tool READ/WRITE Description: Tool status bit = USED

1) Prior to removing the tool from the spindle, the values in the CNC wear tables will be written to the tag.

2) The used tool value in the CNC will be written to the tag.

Tool READ/WRITE Description: Machine ID mismatch

1) Tool pot value on tag is compared to tool pot in which tool resides. If not coinciding, then an alarm is generated.

2) If the machine ID on the tag does not match the machine ID in ToolConnect, then the Machine ID set in ToolConnect is programmed on the tag.

3) The tool geometry and wear values from the tag will be written to the CNC offset table.

4) The full and used life values on the tag will be written to the tool life table in the CNC, provided that the assigned tool group.

Results

- Reduced setup time

- Eliminated scrap and reworked parts due to incorrect tool data

- Removed operator data entry errors and enabled proper tracking of each tool

- Eliminated machine crashes due to wrong tool loaded