Tool Health Check Application Eliminates Scrap from Runout Caused by Chip Interference

Challenge

This customer was repeatedly machining out of tolerance holes in the engine head due to excessive runout of their tooling. The runout was the result of metal adhering to the taper of the tool holder during a tool change causing the tool to run out when contacting the material.

This resulted in elongated and oversized bored holes on the engine head. The entire engine head had to be scrapped, which was extremely costly and unpredictable, often occurring multiple times per shift.

Solution

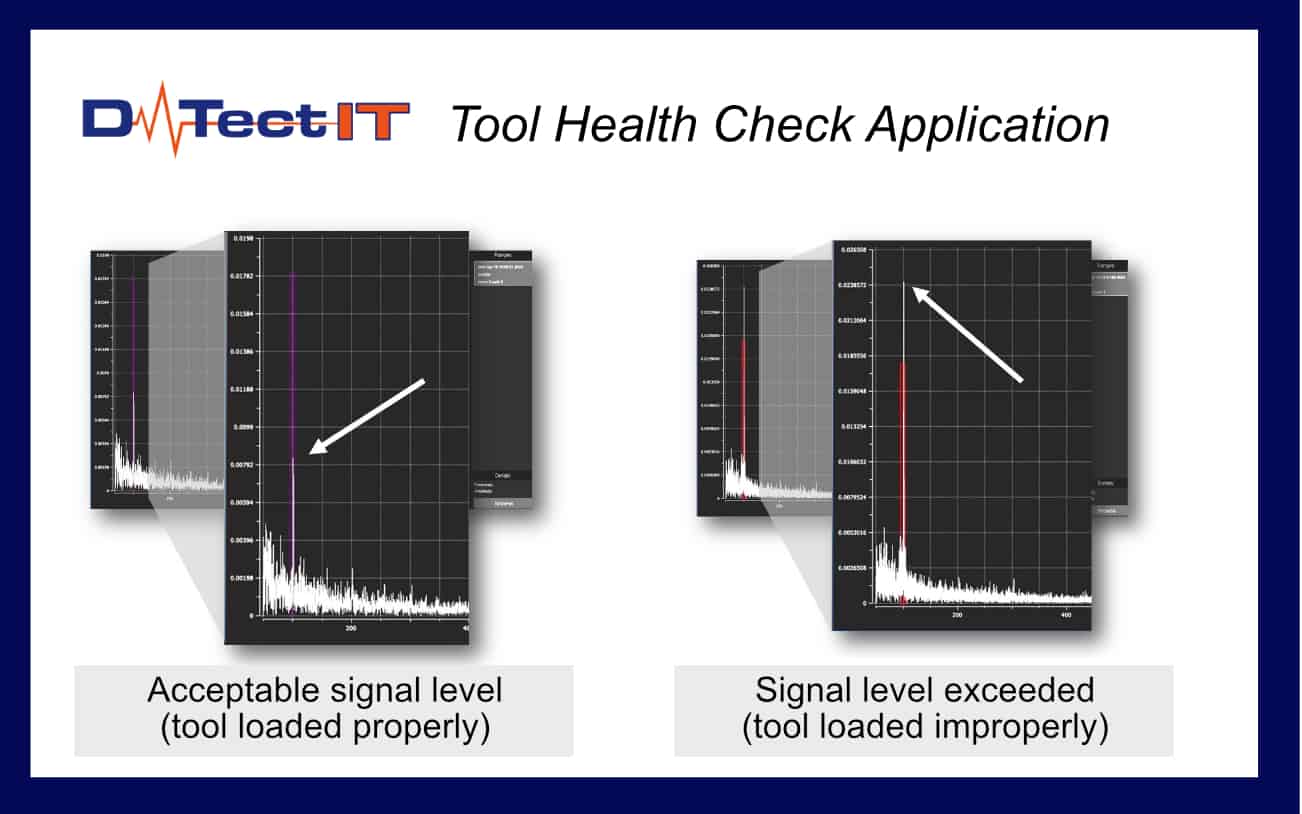

The customer implemented Caron Engineering’s DTect-IT with a vibration sensor to perform a frequency analysis of the rotating tool prior to cutting. The frequency at which the analysis is carried out is based on the RPM of the tool. First, DTect-IT learns the normal magnitude of the tool when properly loaded.

When a chip significant enough to create the runout penetrates the tool clamping area there is a resultant increase in the (vibration) signal amplitude measured with DTect-IT, which will generate an alarm. The part program checks for the DTect-IT alarm and stops the process before a bad part is produced.

The program will then initiate a tool change in response to the DTect-IT alarm to remove and reinsert the tool, attempting to clear the chip from the tool. If this is successful, machining will proceed. If it is unsuccessful, DTect-IT will stop the process and signal the operator to intervene.

Results

- Eliminated scrap

- Maximized machine uptime

- Reduced inspection time (increased process confidence)