Power.

Power.

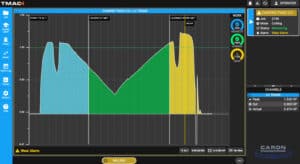

Caron Engineering’s adaptive tool monitoring system, TMAC, measures true motor power as the tool cuts through material to determine if a tool is worn or broken. Static limits based on the learned power of the tool in cut will alarm the machine when not enough power is achieved (no contact with material) or when too much power is achieved (tool is worn or broken). This method protects the machine and tooling; however, it is not always the most precise determination of how the tool is wearing over time.

Power over time.

Caron Engineering’s TMAC system has a work enable option for each tool and section to accurately monitor tool wear by measuring power over time. To do this, TMAC learns the total power consumption for each tool in cut. The learned work is marked against user-defined (wear) parameters to accurately measure tool wear in real-time, as the tool is cutting. As tools gradually begin to fail due to regular operation, the power consumption over time will increase until a wear percentage alarm is triggered. In most cases, when a wear alarm is generated, TMAC will allow the cut to finish and then safely retire the tool. This feature can also prevent nuisance alarms that might generate a small power spike to trigger an alarm. It is also a much more accurate method to determine undercut conditions.

Safeguard the machine.

By using direct communication to the CNC control and measuring tool wear using a high precision power sensor that measures at 200x per second, TMAC is able to react instantly to wear and extreme conditions. Inconsistencies in tooling and material are imminent. If TMAC registers a power spike, indicating a tool has broken during cutting, it will automatically stop the machine and retract the tool before damage can occur. For unattended operations, when worn tools are detected, TMAC can call redundant tooling to keep the operations running smoothly 24/7.

Feed rate optimization.

TMAC also has an adaptive control feature that takes control of the machine tool feed rate in real-time. TMAC learns the target power as the tool cuts through the material and then automatically adjusts the feed rate to optimize the cut. TMAC increases the feedrate through low power cuts and decreases the feed rate through high power cuts and as tools wear. Typical cycle time savings, especially with difficult-to-machine hard and composite materials, is up to 60% (even more in some cases). As a tool wears, the feed rate to maintain a constant power level must be reduced. This feed rate reduction can be used to trigger a wear limit, as an additional method to determine tool wear.

The Data.

TMAC saves and records all cutting data. This is incredibly useful to compare how tools wear over time. TMAC data allows the user to interrogate specific areas of the cut to look at anomalies in the normal cutting operation. If a tool uses inconsistent power over the same cut, the user can overlay these cuts to see what is causing any anomaly. This information can also give TMAC users insight into tool life comparison between different tooling vendors and regrinds.

“Using the TMAC work feature to monitor the power consumption of the tool over time, we can more precisely measure how the tool is wearing, allowing tools to be used to their maximum life. By accurately monitoring tools with high resolution sensors and then seeing a graphical representation of the cutting, the user can diagnose problems much faster and with greater confidence,” said Rob Caron, President of Caron Engineering.