Case Studies - Smart Manufacturing Technology Integration

See how our customers are benefiting from integrating our manufacturing solutions!

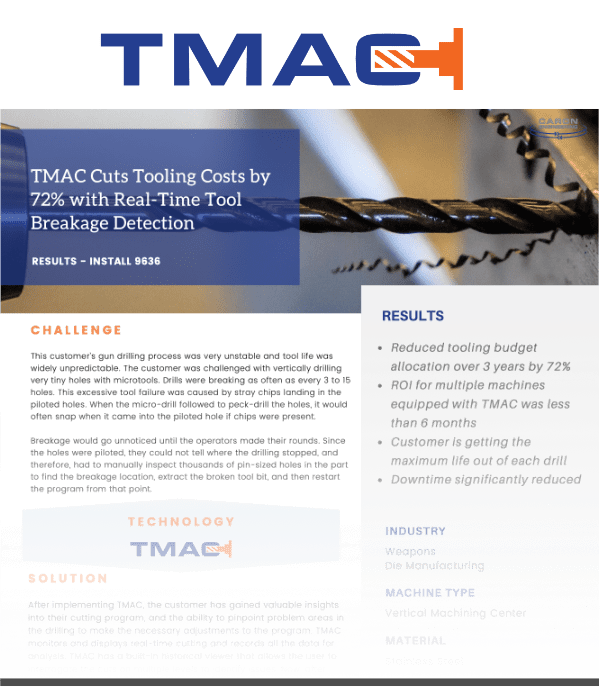

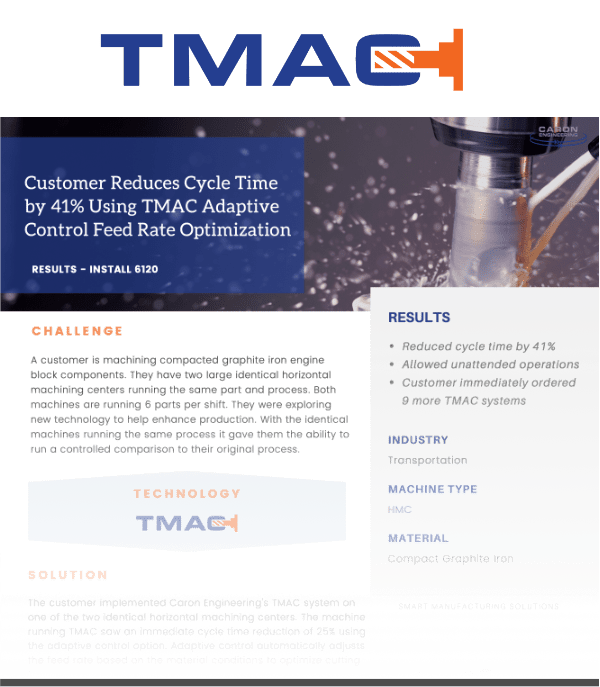

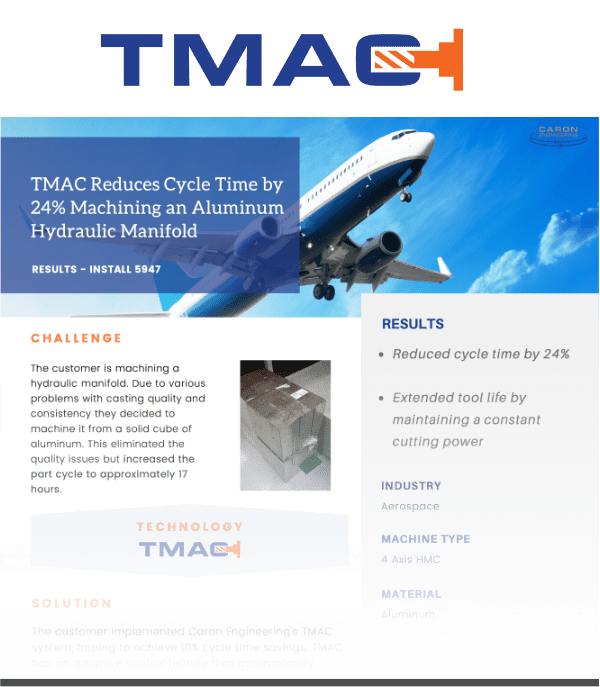

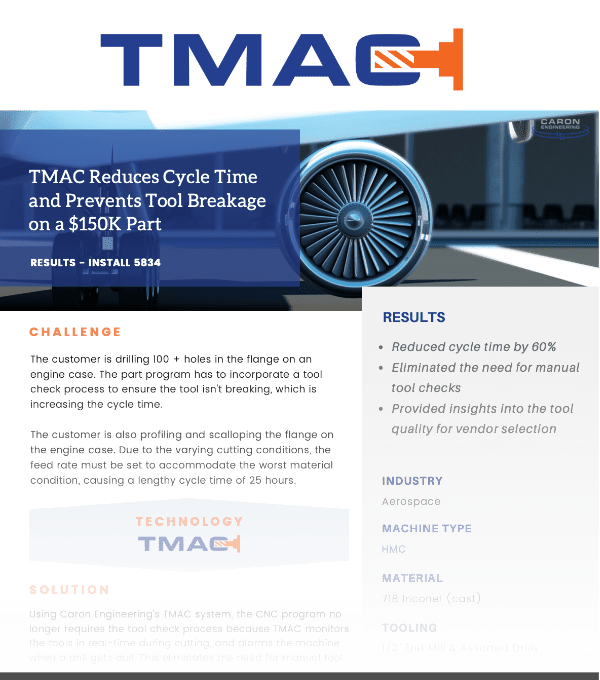

These case studies exemplify how the implementation of Caron Engineering's smart technology systems result in a substantial increase in productivity and profitability. Through automation and process control features, tasks that previously required manual intervention can now be performed autonomously, allowing operators to focus on higher-value activities. With precise tool monitoring, potential issues can be detected and addressed proactively, ensuring maximized tool life and minimizing unexpected downtime due to tool failure or wear. By extending tool life and minimizing scrap, manufacturers can achieve better resource utilization and higher yields, further bolstering the bottom line. In essence, the adoption of Caron Engineering's smart technology solutions not only automate and optimize manufacturing processes but also enhance overall performance, positioning companies for sustained success in today's competitive landscape.