Caron Engineering’s AutoComp software delivers error-free tool offset control. AutoComp is a Windows based software application that processes data from almost any electronic gauging device and updates the tool offsets automatically in the CNC control. All Caron Engineering products interface directly with most CNC controls to optimize machining. AutoComp is doing just that by closing the loop for many manufacturing cells and eliminating costly data-entry errors at the same time.

So, how does it work? (1) The part is machined. (2) The part is measured using almost any electronic gauging device (i.e. wireless calipers, laser micrometers, CMM’s, vision systems, etc.). (3) AutoComp reads the measurement file and compares the data to user programmed compensation limits to determine if compensation is required. (4) AutoComp automatically adjusts tool offsets in the CNC control.

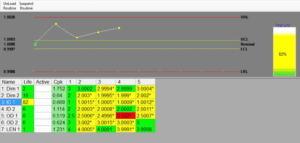

During setup, the user creates an AutoComp routine consisting of the essential part dimensions and inputs the parameters (tolerances and compensation limits) for each dimension. AutoComp reads the measurement file and checks each measurement against the feature limits to calculate the correct amount to offset each tool. AutoComp sends this information to the CNC control automatically, with no operator intervention required.

The built-in PartView feature allows the user to upload a (jpg) picture and visibly associate each area of the part being measured for deviation. The operator can more easily identify which area of the part will be compensated. The measurement blocks are highlighted to clearly see at a glance if the part measurement is good (green), requires compensation (yellow), or is out of tolerance (red).

AutoComp also has the ability to track tool wear and report when a tool change is needed. Each time a tool is compensated, the amount of compensation is saved. When tool compensation has exceeded a user-defined threshold, a wear limit is issued informing the operator that the tool needs to be changed. AutoComp can alsosignal the CNC control to automatically call a redundant tool or stop the machine.

All measurement and compensation data are saved to a file. The data is date and time stamped for future analysis. Additionally, the operator receives real-time status of the useful life for each tool.

AutoComp enables automatic tool wear compensation that maintains part accuracy and eliminates human error, thereby improving product quality and reducing scrap.