Tool identification systems are becoming a highly requested option from manufacturers, especially when purchasing a new CNC machine tool. Many machine tool OEMs offer their own basic proprietary systems which allow tools with RFID tags to be loaded into the machine. Since this option is specified by the OEM and installed at the factory, it is based solely on the builder (OEM) specification, not the end user’s specification. This is very challenging for customers who utilize a variety of different OEM machines and have existing tool ID systems in use.

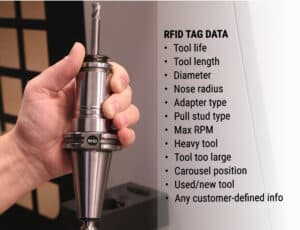

Caron Engineering offers a retrofit tool identification and data management (ToolConnect) system that automatically reads and writes tool presetter data between the machine control and RFID tags embedded in tool holders.

This system uses a customized RFID read station and an intuitive interface tailored to the user’s tool load and unload process. The ToolConnect HMI displays all user-specified tool and process info, along with a tool image to easily verify that the correct tool is being loaded. The system can automatically index to the correct magazine position for further error-proofing of the process on some machine tools.

Improve Operator Efficiency

Caron Engineering’s ToolConnect system can be added to nearly any machine tool as a means to provide a common user interface for every CNC machine on the shop floor, irrespective of builder. This alleviates the inefficiencies of using OEM-specific tool identification that each have their own unique user interface; which might require operators on the shop floor to be educated on multiple different systems, all largely performing the same function. Operators that use ToolConnect only need to be familiar with one type of system with the result being an increase of productivity on the shop floor.

Flexible and Customizable Design

Unlike the rigid specifications of OEM tool identification systems, ToolConnect offers a flexible design that can easily accommodate changes to a process. The system is built specifically to the customers’ requirements, from the (drag and drop) design of the UI to the overall process and functionality of the system. The infrastructure of ToolConnect allows processes to be adjusted and additional functions can be added at any time. Updates can be made by a technician in the field or via remote access by a certified technician. Additionally, ToolConnect offers a large support network through Caron Engineering’s worldwide representation of certified systems integrators.

Compatibility

ToolConnect works with nearly any tool presetter that can write to an RFID tag. ToolConnect easily adapts to new RFID systems, which OEM provided systems are currently not capable of doing.

Benefits

ToolConnect reduces setup time by automating the process of loading and unloading tools into the machine. As an added failsafe, if an operator tries to load an incorrect tool, or a tool in the wrong pot, ToolConnect will alert the operator. This system eliminates the initial in-machine tool measurement and manual entry of tool geometry and wear offsets, providing more chip cutting time. ToolConnect also removes the need for post processors between the tool presetter and CNC.